| SKU | 7000047220 |

|---|---|

| Legacy SKU | 66000201252 |

| UPC | 00051115330452 |

| Product Number | 811632 |

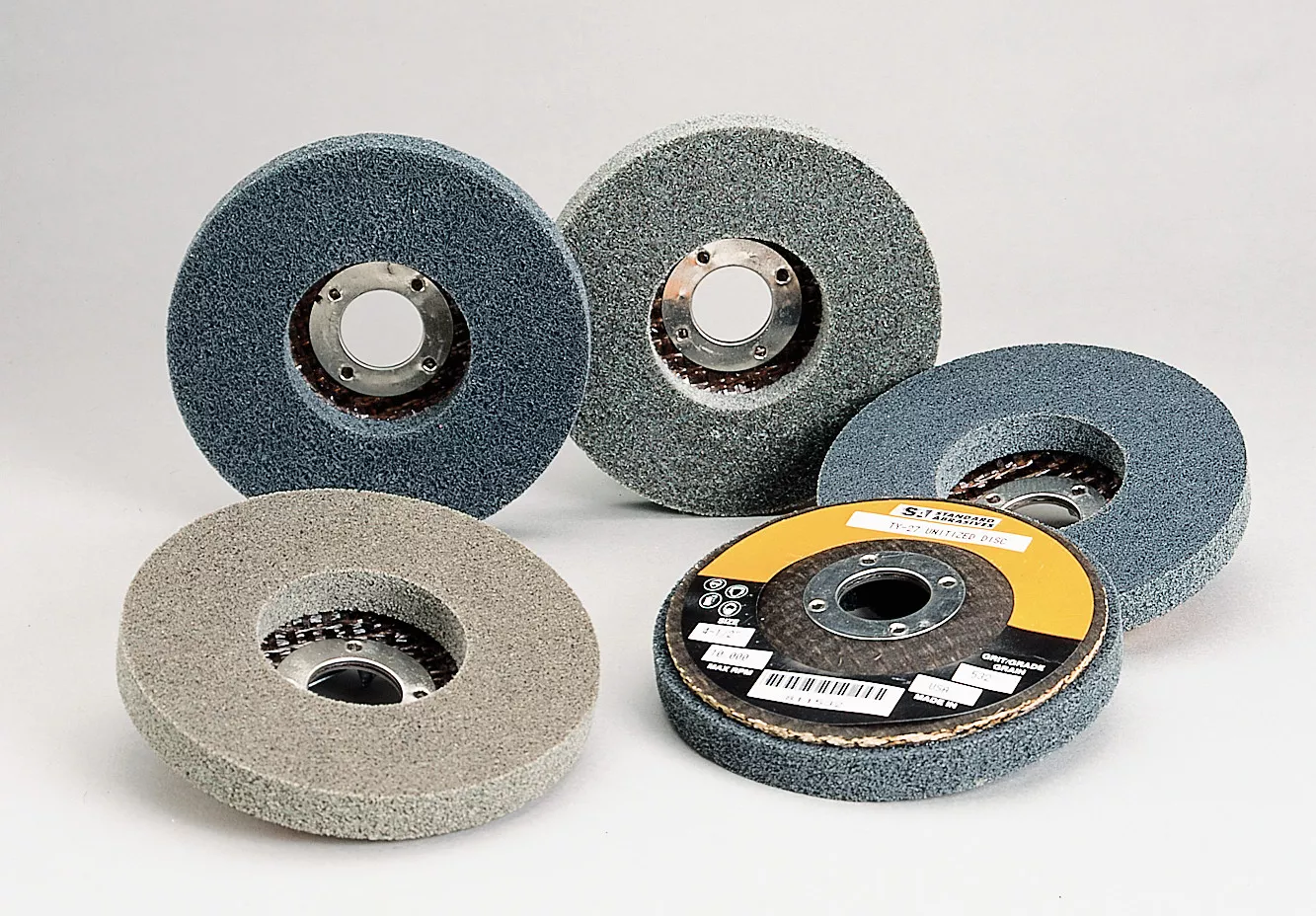

When faced with blending or finishing tricky areas such as internal right angles, choose the Standard Abrasives Type 27 Unitized Wheel - 600 Series for easier access and excellent results. These wheels have a soft to medium density, making them a good match for light-pressure cleaning and blending, and removing small burrs or other surface imperfections.

- 4-1/2˝ Type 27 center hole wheel fits 4-1/2˝ right angle grinder to help reach right angles on the workpiece

- Soft/Medium density material requires light pressure for fine finishing and polishing

- Increased edge durability over the 500 Series offers better cut and adds life for lightweight applications such as blending tool marks and removing surface imperfections

- Silicon carbide mineral suits ferrous and non-ferrous metals, including exotic metals and titanium, as well as composites

- Provides clean, bright surface finish on stainless steel

- Runs clockwise and counterclockwise, allowing greater versatility

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 4-1/2 in | 114.3 mm |

| Thickness | 1/2 in | 12.7 mm |

| Center Hole Diameter | 7/8 in | 22.225 mm |

Shipping Dimensions |

|

| Weight | 12.50021 lb |

|---|---|

| Length | 23.74016 in |

| Width | 9.6063 in |

| Height | 5.11811 in |

| Maximum Speed | 10,000 rpm |

|---|

PRODUCT FAQ

-

What is the composition of 3M's Standard Abrasives™ Type 27 Unitized Wheel 811632, 632?

The Standard Abrasives™ Type 27 Unitized Wheel 811632, 632 is composed of a soft and conformable unitized material with high edge durability. It contains aluminum oxide mineral abrasive.

-

What are the dimensions available for this product?

This particular variant comes in dimensions of 4-1/2 inches x 1/2 inch x7/8 inch.

-

How many wheels can we expect to get per order/package?

There are five (5) pieces available per inner package and an additional fifty (50) packages provided with each case.

-

Is it suitable for heavy-duty tasks?

Yes! Due to its superior construction, our type-27 unitized wheel provides excellent performance when dealing with heavy-duty tasks such as blending edges or deburring sharp corners effectively.

The Standard Abrasives™ Type 27 Unitized Wheel - 600 Series has a soft to medium density when compared to the rest of the Standard Abrasives™ Unitized Block line. It is designed with increased durability over the 500 Series wheels. Constructed with fine grade silicon carbide, this double-duty abrasive combines durability with a fine scratch pattern, making it a great choice for projects that require an aggressive cut yet soft finish – namely, tough blending and polishing applications.

For polishing, the Standard Abrasives™ 632 Unitized Wheel with silicon carbide is a great choice for polishing aircraft parts, polishing after weld removal, and polishing mold and die, cast aluminum, brass, and copper. It is also a good match for finishing surgical instruments and prosthetics. When working with stainless steel, choose this wheel for a clean, bright surface finish.

Due to its conformability, this wheel is great for projects with strict tolerances because it responds to surface irregularities without gouging or undercutting the part. After prolonged use, the wheel may be dressed to maintain its shape.

Type 27 Fits 4-1/2˝ Right Angle Grinder

A 4-1/2˝ Type 27 Wheel (sometimes called a Type 27 Disc) is designed to fit a right angle grinder with a wheel guard, typically used for fiber discs, flap discs, and grinding wheels. Type 27 Wheels have a depressed center to allow grinding at any angle without damaging the surrounding surface with the attachment nut, and are particularly useful for working on internal angles. These unitized wheels are used in conjunction with, and sometimes in lieu of, a coated abrasive resin fiber disc or flap disc. Standard center hole and quick change unitized wheels are also available in a range of sizes (sold separately).

Non-Woven Unitized Construction Offers a Step Up in Density and Durability for Stubborn Surfaces

Standard Abrasives™ Unitized Wheels are a great match for tough deburring, cleaning, blending, and finishing applications. They come in a broad range of densities and grades to suit different metals, the degree of aggressiveness required, shape of the part, and desired finish. Although used for some of the same tasks as Standard Abrasives™ Buff and Blend products, they are designed with a far stronger and denser construction to support more aggressive applications and accomplish material removal more rapidly. Even though unitized wheels are much stiffer products, the non-woven nylon fibers of the wheel maintain the advantage of responding to surface irregularities while preserving the geometry of the piece, and produce a consistent finish.

Unitized wheels are created by starting with layers of open web material that combines non-woven fiber strands and abrasive mineral with a tough resin bond. These layers of web are then cured and compressed together. By fusing layers of open web, the abrasive gains more toughness and durability, so it can withstand repeated wear.

Ultimately, the wheel's durability is what makes it such a good match for edges. The wheel is tough enough to complete high-pressure edgework without tearing or otherwise disintegrating. Regardless of the diameter or thickness of the wheel, it maintains its structural integrity to remain a stiff and long-lasting abrasive even under high pressure. Additionally, as the layers wear, the wheel can be dressed to maintain its shape.

Load-Resistant Construction Boosts Life and Performance

Standard Abrasives™ Unitized Wheels are load-resistant to keep you cutting with fresh mineral. The gaps in the open web allow unwanted swarf to escape. Consequently, less debris clogs the abrasive, so the mineral can stay fresh, keep cutting sharp, and deliver a consistent cut over the life of the product. As the fibers break down and fresh mineral is exposed, it reduces the likelihood of dull or blunt mineral smearing the surface, contributing to cleaner surfaces and less re-work. Furthermore, manual fatigue that may result from applying heavy pressure to a dull abrasive is reduced.

The Many Benefits of Standard Abrasives™ Non-Woven Products

Standard Abrasives™ Unitized Wheels offer many benefits for heavy-duty jobs. For all the aforementioned reasons, Standard Abrasives™ Unitized Wheels invigorate deburring, cleaning, blending, and finishing applications by helping operators reduce finishing steps, minimize costs, and achieve greater throughput.