| SKU | 7010328715 |

|---|---|

| Legacy SKU | 61500064565 |

| UPC | 00048011142814 |

| Product Number | SC-BS |

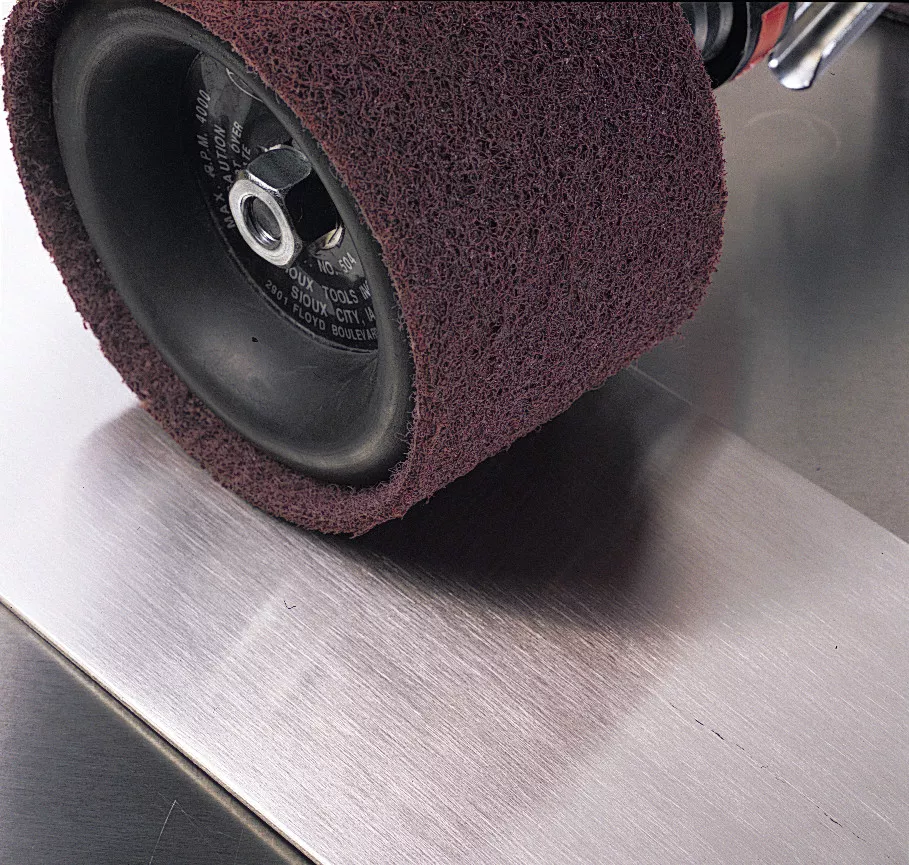

Scotch-Brite Surface Conditioning Belt is a durable belt engineered to perform detail work such as blending, blending corners, cleaning, contour finishing, deburring, deburring edges, fine finishing, flat finishing, setting the grain, stainless steel finishing, and attaining straightline-brushed finishes on a variety of metals.

- Nonwoven, surface conditioning belts clean, blend, deburr and finish

- Reduced loading and heat build-up allow extended operating time and consistent surface conditioning results

- Conformability allows abrasive to stay in contact with complex-shaped parts in robotic processing

- Reinforced backing and nonwoven open web material provide superior flexibility for detail work, over contours and edges

- Removes surface imperfections, grind lines, mill, and other marks

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 3.226 lb |

|---|---|

| Length | 16.6 in |

| Width | 16.5 in |

| Height | 5 in |

| Color | Blue |

|---|

PRODUCT FAQ

-

What is the size of 3M's Scotch-Brite Surface Conditioning Belt, SC-BS?

The size of our Scotch-Brite Surface Conditioning Belt, SC-BS is 1-1/2 in x 132 in.

-

How many belts are there per case and what will it cost me?

Our product comes with a total of 5 belts per case. For pricing information, please contact your local retailer or distributor.

-

What does A/O Very Fine mean and how does this impact my use of the belt?

A/O stands for Aluminum Oxide while "Very Fine" refers to the abrasive grit. This means that our surface conditioning belt has finer abrasives which makes it ideal for light cleaning tasks such as removing rust or paint without damaging surfaces.

-

. Can I use this belt on any type of material?

. Yes, you can use our coat conditioners smoothly across metals, composites and plastics.

-

. Is this product durable enough for heavy-duty jobs like deburring sharp edges or welding marks?

. While it is not specifically designed for extreme cuts or heavy-duty grinding jobs, its non-woven fiber construction gives it enough strength to clean up surfaces after extensive metalworking operations like welding projects or grinding welds down to flatness level where they contribute to achieving high-quality finishing outcomes under optimum conditions when handled properly by skilled personnel with adequate training inclusive of hazard identification measures implementation when required during sectional applications requirements meeting regulatory safety standards adherence guidelines compliance considerations that vary depending on industrial locations anywhere around the globe on different countries' environments regulatory context frameworks variability criteria including protective equipment requirements among others then certified instructors administer personalized instructions based on assessment evaluations considerations compliant with workplace safety regulations enforcement by reputable fir

Scotch-Brite™ Surface Conditioning Belt is a versatile abrasive that works well to remove coarse grind lines, mill marks, or small burrs left by cutting tools or conventional abrasives. These abrasive belts come in many different widths and lengths and are used on a variety of different belt sanding tools for many different applications on both wood and metal.

Ideal for Robotic FinishingWith a wide range of conformability options and high consistency, long-lasting Scotch-Brite™ industrial abrasives are a great option for robotic metal finishing. Scotch-Brite™ Surface Conditioning Belts can generate a spec-required, aesthetic finish when used in both manual and robotic processing.

Choose the Right Belt for You3M offers a broad selection of belts to fit most any industrial belt sander. Wide belt sanders are used for sanding and finishing large wood panels. Medium-width belts fit onto edge or portable belt sanders for sanding or blending wood pieces such as cabinet doors, and narrow belts are used with file tools in metalworking to access small areas or inside corners.

Hard-Working Minerals: Aluminum Oxide and Silicon CarbideScotch-Brite™ Surface Conditioning Belts are manufactured with a choice of silicon carbide or aluminum oxide abrasive mineral. Silicon carbide is a synthetic mineral that is very sharp and commonly used for low-pressure applications such as paint prep and finishing. Aluminum oxide is a hard, blocky mineral that provides high cut-rate and long life. While silicon carbide breaks down faster than aluminum oxide, it produces a finer finish.

An Alternative for Wheels and DiscsBelt sanders are used for rapid grinding, sanding and finishing on a variety of surfaces. Depending on the material being worked, sanding wheels and discs may clog, quickly making them less efficient, while belt sanders continue to sand without clogging because small grooves in the abrasive belt open as they go around the arc of the drive wheel.