| SKU | 7000000786 |

|---|---|

| Legacy SKU | 61986510354 |

| UPC | 00048011037660 |

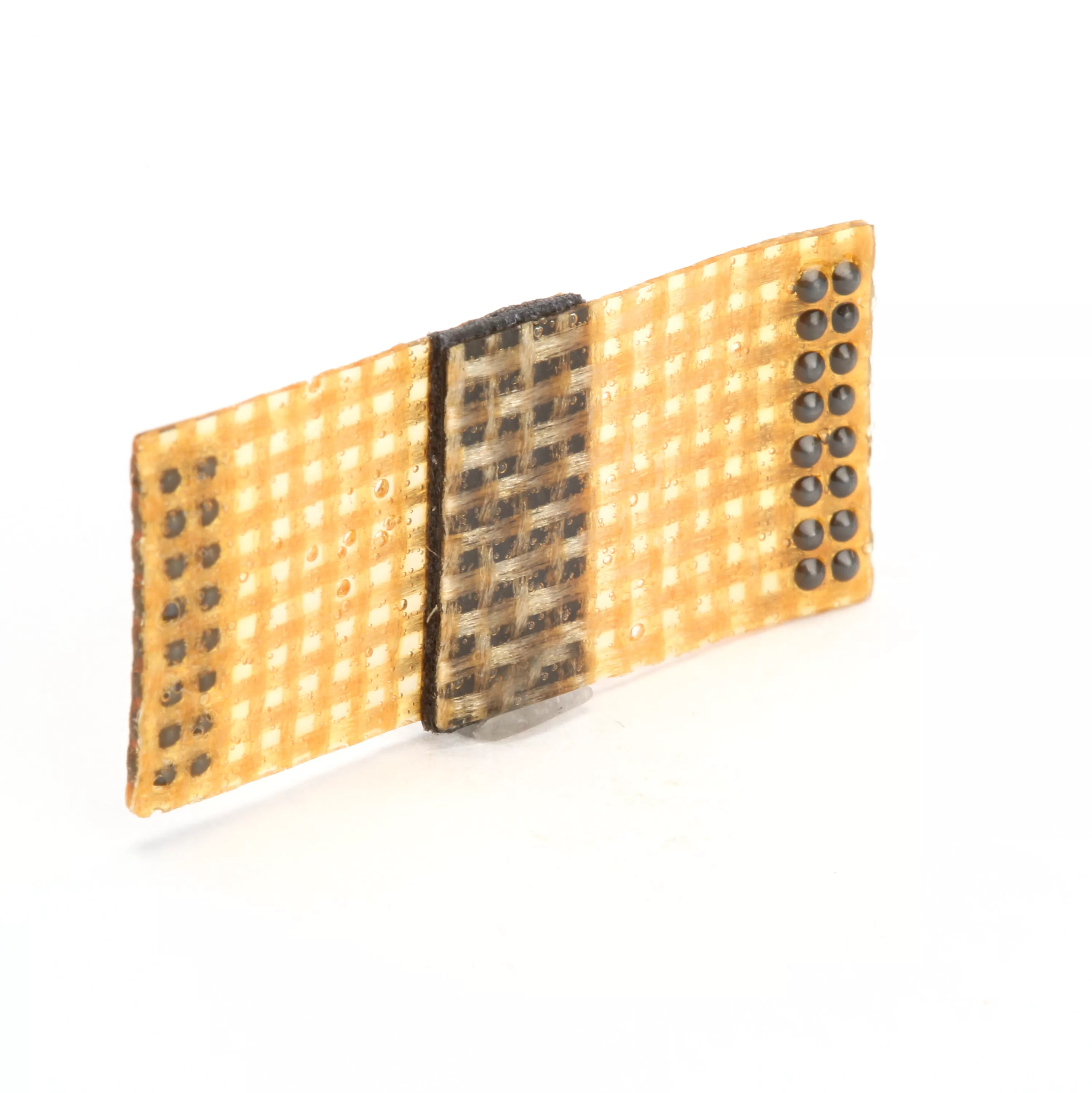

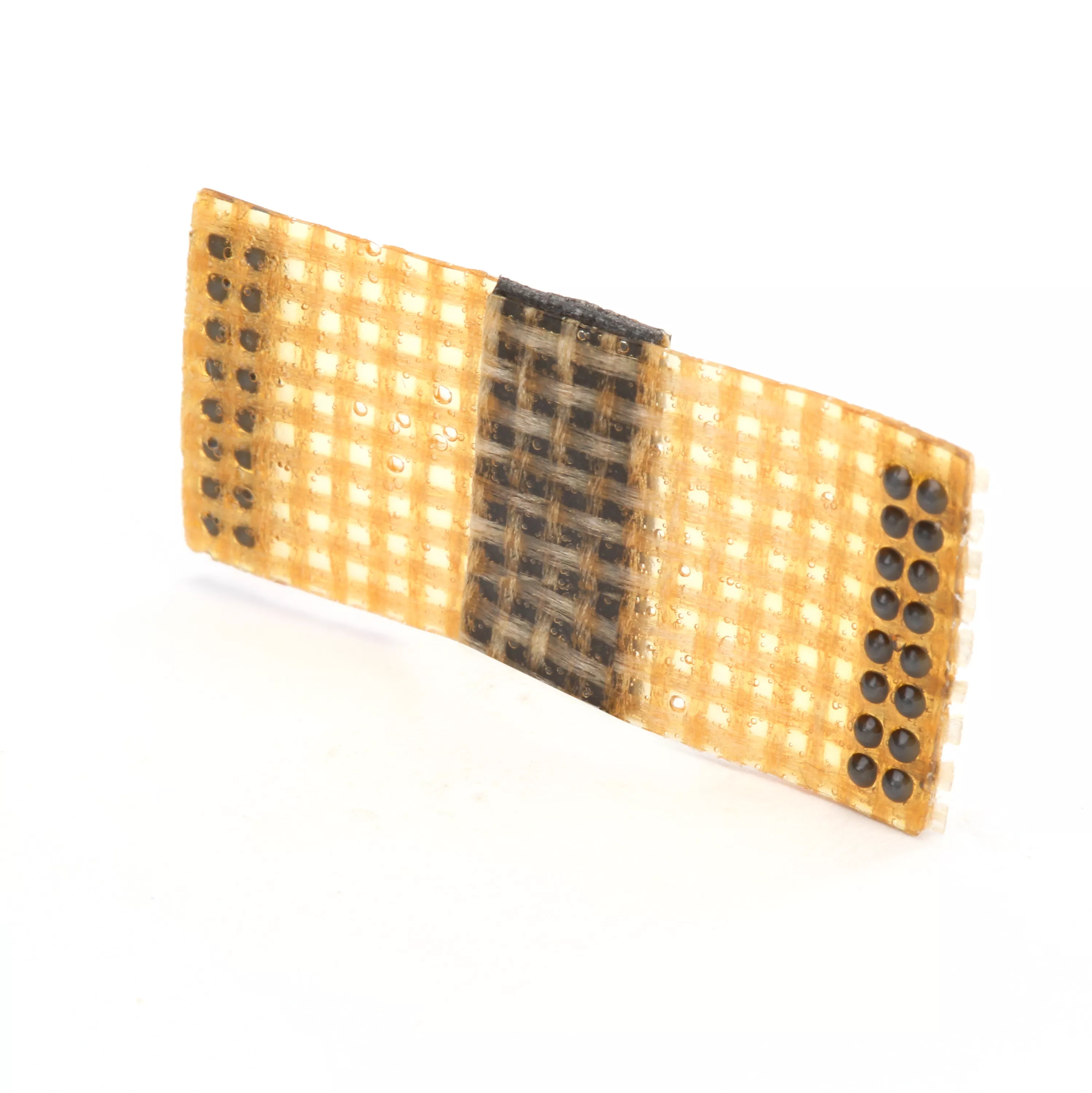

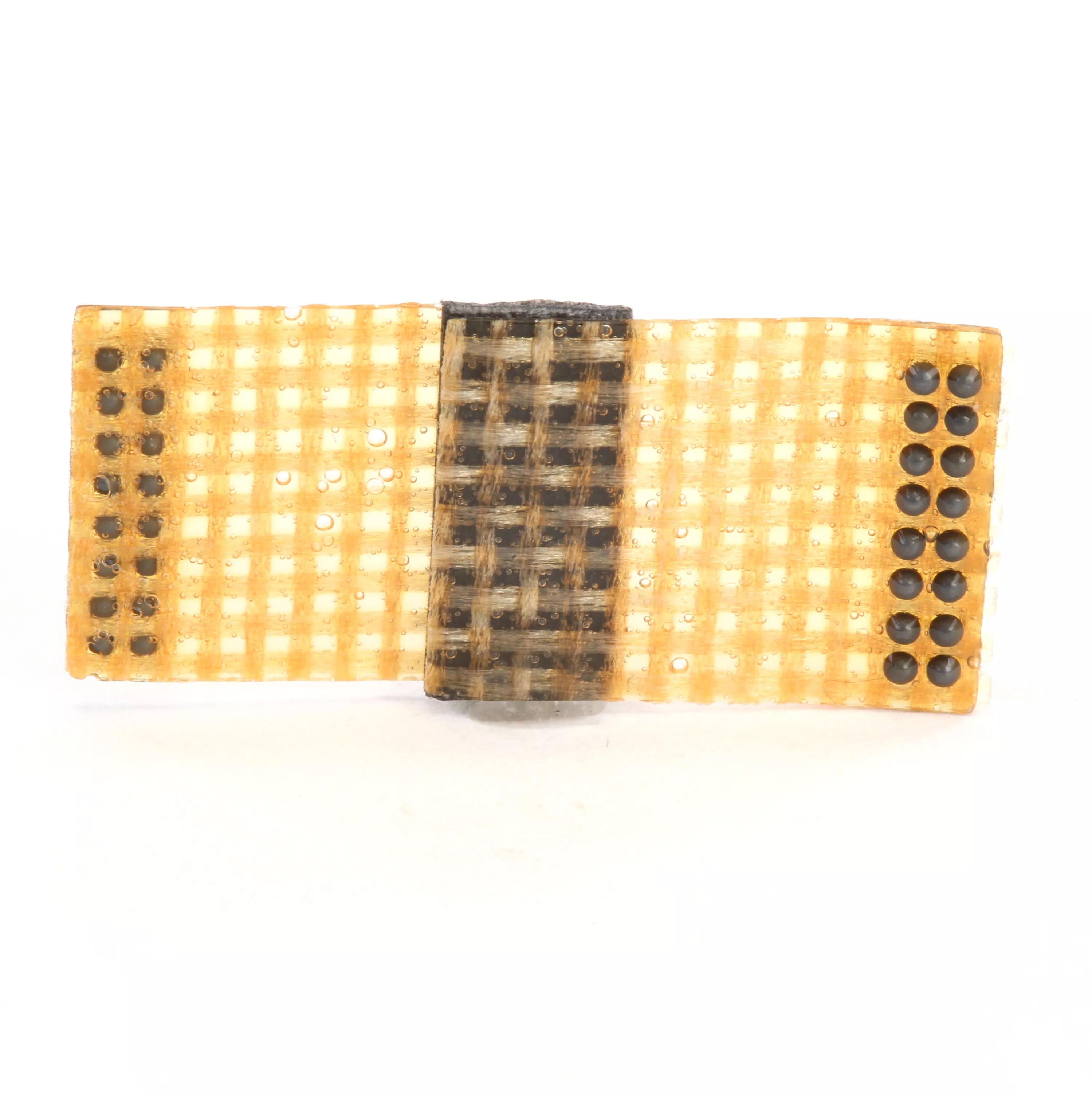

The 3M Roto Peen Flap Assembly effectively peens a variety of metals.

- Flap/mandrel assembly is portable for added convenience

- Tungsten carbide shot is bonded to the flaps, providing a cleaner peening method than loose shot "blasting"

- Available in three flap sizes for both small and large surface areas

- Especially effective for precision in-service rework, manufacturing, repair of small areas, and peening holes

- Imparts a compressive residual stress that benefits the material by strengthening its durability

Product Dimensions |

Imperial | Metric |

| Weight | 0.0054 lbs | |

|---|---|---|

| Width | 4 in | |

| Length | 0.06299 in | |

| Height | 3 in |

Shipping Dimensions |

|

| Weight | 0.181 lb |

|---|---|

| Length | 6.37795 in |

| Width | 4.68504 in |

| Height | 4.68504 in |

| Color | Goldenrod |

|---|

PRODUCT FAQ

-

Sure, here are some possible questions and answers

What is the size of the 3M™ Roto Peen Flap Assembly?

-

The size is 9/16 in x 1 1/4 in.

How many pieces come in each case?

-

There are a total of 10 flap assemblies per case.

What does TC 330 stand for in the product description?

-

TC stands for "Tough Cut" which indicates this product has a durable construction suitable for tough applications. The number "330" refers to its level of toughness within our product range.

Can this flap assembly be used on different materials?

-

Yes, the 3M™ Roto Peen Flap Assembly is designed to work effectively on a variety of materials including metals and composites.

Is there any special maintenance required for these flap assemblies?

-

No special maintenance is needed beyond typical care during use. Just follow standard operating procedures and store them properly when not in use.

The 3M Roto Peen Flap Assembly is a unique and portable tool designed for peening metal surfaces. It consists of a flap and mandrel, utilizing captive shot-flap technology. The flaps are made of flexible material with tungsten carbide shot adhered to them using high-strength resin. These flaps are then bonded together with a special adhesive, allowing for easy placement in a flap mandrel.

Peening is a cold working process that applies repeated stress to the surface of a material, resulting in increased strength through compression. This method helps improve the material's resistance to fracture, fatigue, and stress corrosion cracking. Traditional shot peening methods involve spraying the work surface with cast steel shot, which can release debris and limit the operator's workspace.

The 3M Roto Peen Flap Assembly eliminates the need for a sandblaster or abrasive materials, as the tungsten carbide shots are already attached to the flaps. This unique construction offers two main benefits. Firstly, it provides a cleaner peening process by minimizing debris release as the flaps abrade the surface. Secondly, it is portable, making it more convenient for operators to use.

The flap/mandrel assemblies are particularly effective for precision in-service rework, manufacturing, repair of small areas, and peening holes. The 3M Roto Peen Flap Assembly is available in three sizes, allowing for peening on various surfaces and radii areas. The uniform TC-330 shot size ensures consistent results. As the part is peened, a compressive residual stress is created, forming a non-yielding layer that enhances the material's ability to resist fatigue, stress, and fracturing.

The speed of flap rotation is the most crucial factor affecting peening intensity. Increasing the rotation speed intensifies the peening, while decreasing the speed reduces the intensity. To achieve uniform peening coverage, operators should use a circular or oscillating motion over the entire area.