| SKU | 7000045692 |

|---|---|

| Legacy SKU | 60980025062 |

| UPC | 00051144849932 |

| Product Number | 84993 |

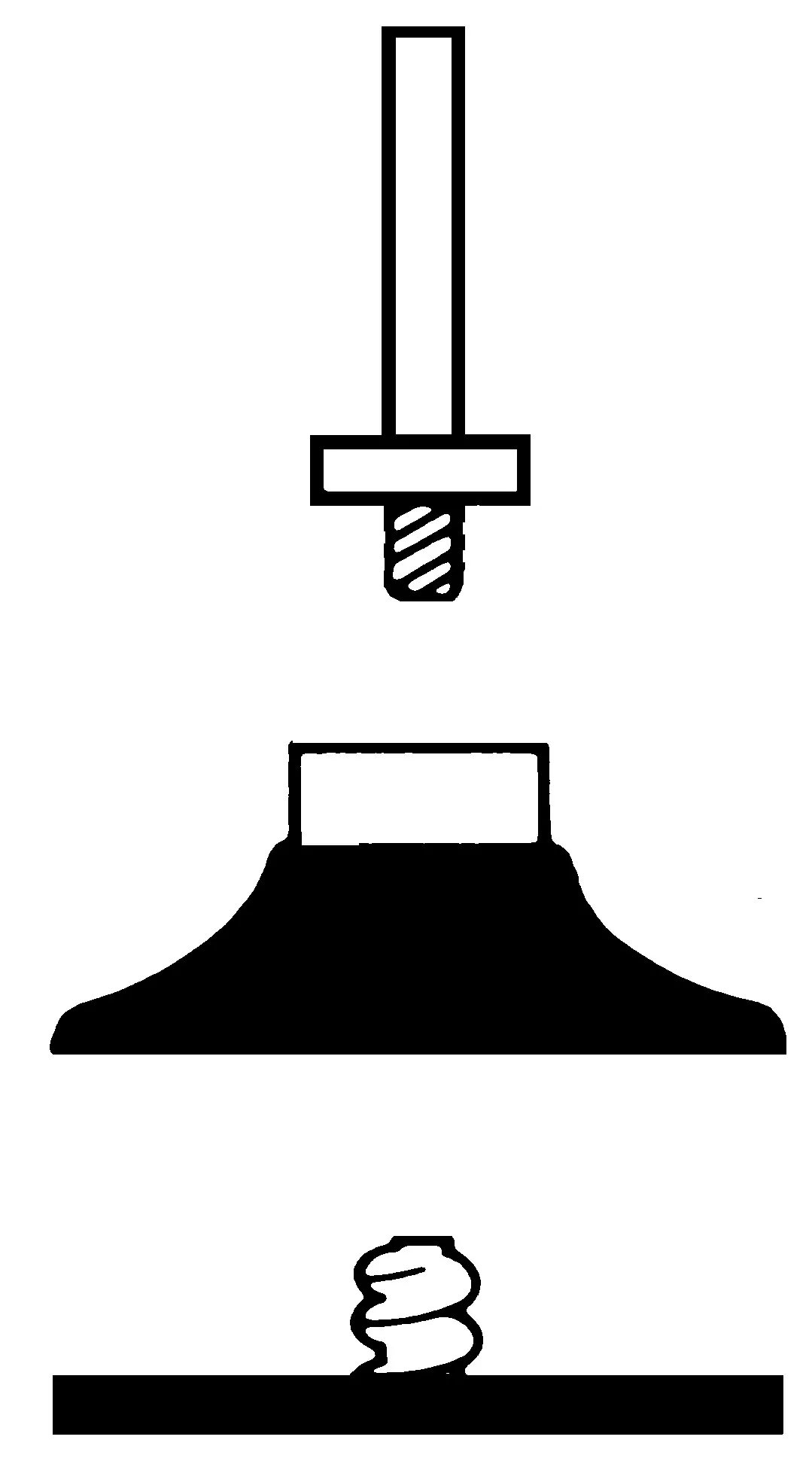

3M Roloc Disc Pad optimizes the performance of our 3M Roloc discs and bristle discs by providing the right backup system and a secure attachment for grinding applications. Plus it saves time by eliminating the need to align edges of the disc with the disc padthe screw aligns the disc, making disc changes quick and easy.

- SECURE ATTACHMENT: Disc pad provides secure attachment for any 3M™ Roloc™ disc or bristle product

- VARIOUS DIAMETERS AND HARDNESS: Pads come in various diameters and levels of hardness to meet the requirements of many different grinding applications

- QUICK AND EASY ATTACHMENT: Disc attachment is quick and easy, increasing productivity

- VERSATILE SYSTEM: Works with drills, disc sanders, right angle grinders, and rotary sanders

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 2.95276 in | 75 mm |

| Thickness | 0 np | 0 NP |

| Center Hole Diameter | 0.0 NP |

Shipping Dimensions |

|

| Weight | 1.29985 lb |

|---|---|

| Length | 12.59843 in |

| Width | 9.2126 in |

| Height | 2.04724 in |

| Color | Black |

|---|---|

| Maximum Speed | 20,000 rpm |

PRODUCT FAQ

-

What is the purpose of 3M's Roloc Disc Pad TR 84993?

The purpose of 3M™ Roloc™ Disc Pad TR 84993 is to provide a secure attachment method for quick and easy disc changes in applications requiring extra hard density.

-

What size are the discs compatible with this pad?

This pad features an M14-2.0 internal thread for compatibility with industry-standard angle grinders and other power tools, and accommodates discs measuring 75 mm in diameter.

-

How many pads do I get per case when I order these products?

Each case yields five pads, giving customers ample supply replacement over time.

-

Is there anything else I need to know about using these pads in my business or operations ?

It’s important that you use these pads according to their intended application. Make sure your power tool has sufficient RPMs before attaching the back-up pad. Always follow safety guidelines while working on any project, no matter how big or small it may be.

Product Description: 3M™ Roloc™ Disc Pad

The level of hardness required for a task depends on its aggressiveness. For more aggressive applications, a higher density is recommended, while a lower, more flexible density is suitable for less aggressive applications. The user's work style also plays a role in determining the appropriate density. These disc pads are compatible with any drill, disc sander, right angle grinder, or rotary sander. The maximum RPM is determined by the size and firmness of the disc and disc pad.

The 3M™ Roloc™ Disc Pad is designed to be used with the following Roloc attachment systems: TR, TP, and TS. It is important to select discs with the attachment design made for the correct system.