| SKU | 7000100771 |

|---|---|

| Legacy SKU | WT300955786 |

| UPC | 00051115527739 |

| Catalog Number | 5571-10 |

| Product Number | 5571 |

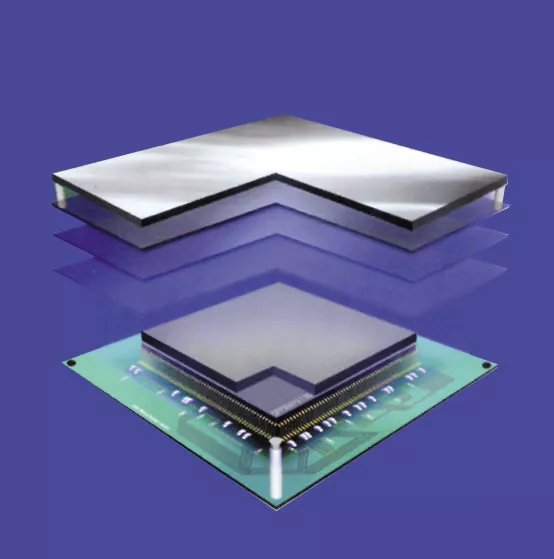

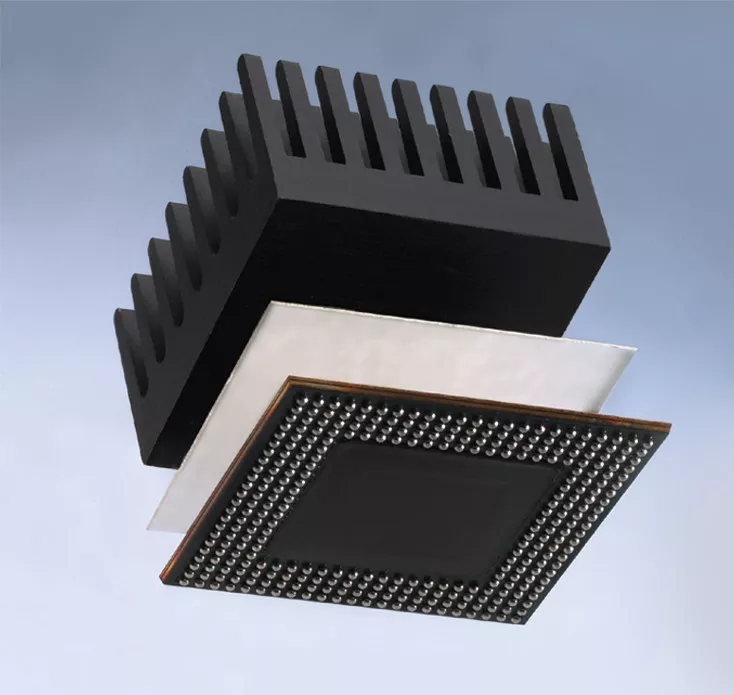

3M Thermally Conductive Acrylic Interface Pad 5571 is designated to provide a preferential heat transfer path between heat generating components like integrated circuit chip and heat spreaders as aluminum heat sink.

- High thermal conductivity, 2.0 W/m-K on plane direction

- Good softness and conformability even to non-flat IC surfaces and heat spreading blocks

- Passes UL 94 V-0 flame retardance test

- No siloxane outgassing or oil bleeding

- Soft compliant material allows for pressure relaxation, preventing high pressure zones on components

- Good electrical insulation properties

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Thickness | 39.37 mil | 1 mm |

Shipping Dimensions |

|

| Weight | 22.04623 lb |

|---|---|

| Length | 13.77953 in |

| Width | 9.84252 in |

| Height | 9.84252 in |

| Color | Yellowish White |

|---|

PRODUCT FAQ

-

What is the purpose of 3M™ Thermally Conductive Acrylic Interface Pad 5571-10?

The purpose of this interface pad is to provide reliable thermal management and high-performance bonding for electronic devices.

-

What are the dimensions of this product?

This product comes in a roll with a width of 300mm and length of 20m, ensuring that you have enough material to suit your needs.

-

Does it require any special storage conditions?

Yes, we recommend storing this product at room temperature and away from moisture or direct sunlight until it is ready for use.

-

Can I cut the pad into smaller pieces to fit my specific application?

Absolutely! The interface pad can be easily cut into custom shapes or sizes using standard cutting tools making it suitable for most applications.

-

. How can I get more information about this product if needed?

. If you need more information about our Thermal Management solutions, including information on choosing the right thermally conductive pads & tapes please contact our technical support team who will be glad to assist you further.

3M™ Thermally Conductive Acrylic Interface Pad 5571 has a medium-soft pad that conforms to uneven substrates, providing excellent wettability to fill gaps for improved thermal performance. The thin, firm, low-tack layer provides easy handling for pre-assembly and die-cutting. This pad provides robust thermal management for applications in a variety of market segments, such as consumer electronics, automotive, LED lighting, medical devices, communication infrastructure, and aerospace & defense.

Our family of 3M™ Thermally Conductive Acrylic Interface Pads provide low-outgassing and high-performance solutions compared to silicone. These acrylic pads have no siloxane VOC or oil bleeding, which are associated with silicone products and can often cause device failure. They are lightweight, making them ideal for applications with finer spacing requirements and a small footprint. 3M™ Thermally Conductive Acrylic Interface Pads have good electrical insulation properties to protect against electrical interference and device breakdown.

Recommended Applications:

- Heat transfer between PCB and heat sink

- Decrease of compression stress to electronic parts by thermal pad softness

- Gap filling in electronic devices

- Chip on film (COF) heat dissipation

- Power electronic component thermal management

Examples:

- LED displays

- Electric vehicle (EV) batteries

- Wireless charging units

- Satellite navigation

- Sensors

- Process control equipment

- Test & measurement devices