| SKU | 7000119275 |

|---|---|

| Legacy SKU | 60440235327 |

| UPC | 00051111558386 |

| Product Number | 481W |

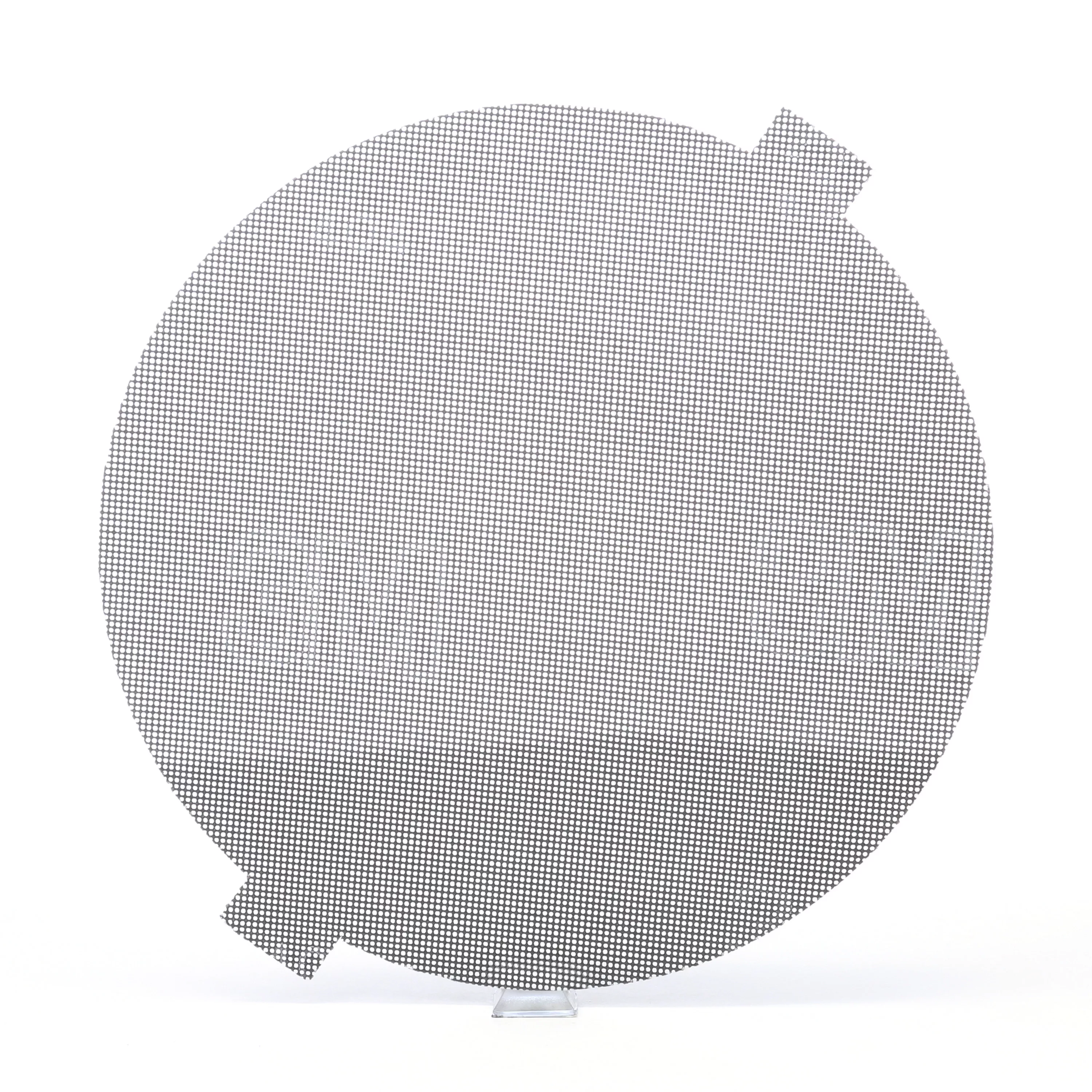

The 3M Wetordry Cloth Disc 481W was designed to help operators finish metal surfaces, as well as prep them for paint. Wetordry cloth may be run wet or dry and helps rid your workpiece of unwanted coatings and corrosion.

- Fast-cutting silicon carbide mineral leaves a consistent scratch pattern while reducing the need for heavy manual pressure

- May be used for paint prep

- Sands a variety of substrates, from metals to hardwoods

- Water-resistant polyester backing means cloth may be run wet or dry

- A good alternative for compounds and lubricants

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 8 in | 203.2 mm |

| Center Hole Diameter | 0 NP | 0.0 NP |

Shipping Dimensions |

|

| Weight | 3.78754 lb |

|---|---|

| Length | 11.3 in |

| Width | 8.9 in |

| Height | 9.3 in |

| Color | Black |

|---|

PRODUCT FAQ

-

What is the size of the 3M™ Wetordry™ Cloth Disc 481W?

The diameter of this disc is 8 inches with no holes.

-

How many discs are included in each case of the 3m™ Wetordry™ Cloth Discs?

Each case consists of a total of 250 individual cloth discs.

-

Can I use this product for wet sanding or dry sanding?

: Yes, sure you can! This product has been designed to perform superbly both when used wet and dry.

-

Is it possible to order less than a case quantity?

: Unfortunately not as we currently offer these specific discs only by full cases, but please know that our sales department may be able to assist if you have very specific needs!

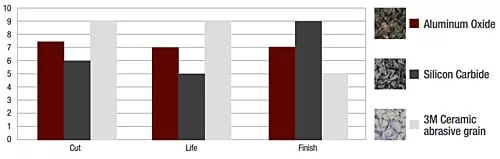

3M™ Wetordry™ Cloth Disc 481W features silicon carbide – a mineral that is very sharp and commonly used for low-pressure applications such as paint prep. Although it breaks down faster than aluminum oxide, silicon carbide produces a superior finish. To achieve a consistent scratch pattern that is often desirable for final finishing, users apply light pressure. One of its greatest features is its versatility – it may be used on a variety of substrates including metals, whitewood, softwood, and hardwoods. 3M™ Wetordry™ Cloth Disc 481W is used with a disc pad holder, so operators can abrade the workpiece by hand.

The Benefits of Cloth-Backed DiscsThe cloth backing on this disc is a durable, water-resistant polyester screen. Our 3M™ Wetordry™ products are engineered to include our proprietary waterproof cloth backing, which supports both wet and dry applications. Cloth-backed discs are known for their durability and flexibility, making them a good first choice when working with metal or for heavy wood stock removal. However, these applications tend to produce a significant amount of dust, which can clog the abrasive points and create an inferior work environment. These effects may be minimized by sanding with water to rinse dust away from the workpiece and the abrasive surface.

Some technicians prefer using the abrasive dry because they can quickly inspect the work. With wet sanding, water is used as a lubricant. This keeps the abrasive clear of loading and can prolong the life of the abrasive.