| SKU | 7000120106 |

|---|---|

| Legacy SKU | 60455067003 |

| UPC | 00051131303621 |

| Catalog Number | 30362 |

| Product Number | 443SA |

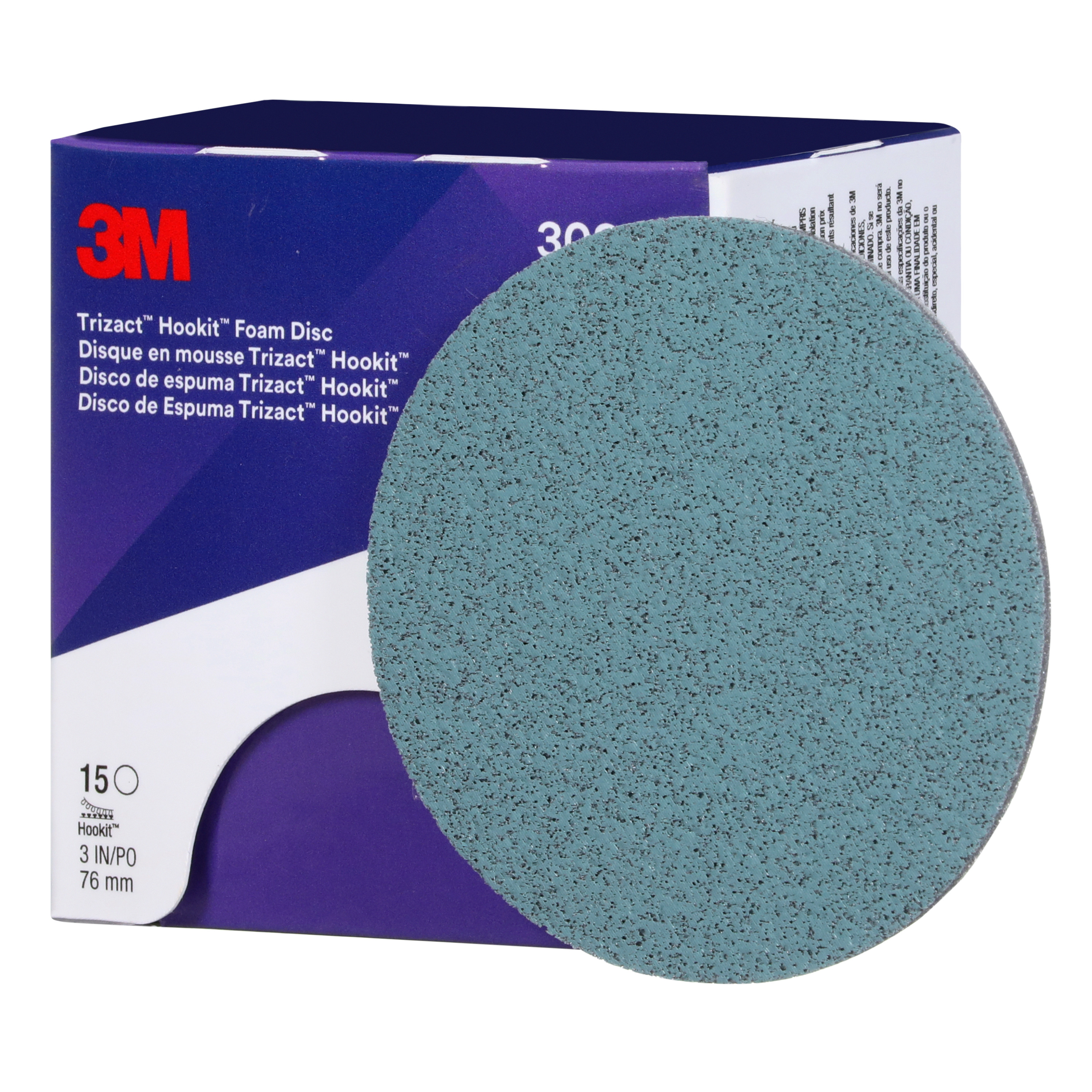

Spend less time compounding and enjoy less risk of defects by using 5000-grade 3M Trizact Hookit Foam Abrasives. Use these discs as the next step to refine 3000-grade scratches, to reduce compounding. 3M Trizact abrasives are engineered for consistent cut and long life.

- Reduce the need for compounding with 5000-grade 3M™ Trizact™ Hookit™ Foam Abrasive Discs in your paint finishing.

- These 5000-grade foam discs are used as the next step after 3M™ Trizact™ 3000-grade sanding to further reduce the time required for compounding.

- Used damp, they refine inconsistent sand scratches with less loading than dry sanding.

- 3M™ Trizact™ abrasives have unique three-dimensional abrasive structures which are distributed across the abrasive surface. As the structures wear, fresh sharp mineral is exposed delivering consistent finishes, longer disc life and helping reduce material costs.

- Allows technicians to refine paint scratches using a lighter dual-action sander instead of a heavier polisher.

- Compared to traditional buffing, using 3M™ Trizact™ Abrasives for removing sand scratches can reduce the possibility of heavy swirl marks, burn through, and other defects caused by more aggressive processes.

Product Dimensions |

Imperial | Metric |

| Weight | 0.13294 lbs | |

|---|---|---|

| Width | 3.11024 in | |

| Length | 3.11024 in | |

| Height | 1.9685 in | |

| Diameter | 3 in | 76.2 mm |

| Center Hole Diameter | 0 NP | 0.0 NP |

Shipping Dimensions |

|

| Weight | 0.69997 lb |

|---|---|

| Length | 6.77165 in |

| Width | 4.76378 in |

| Height | 3.97638 in |

| Color | Blue |

|---|

PRODUCT FAQ

-

What is the purpose of 3M™ Trizact™ Hookit™ Foam Disc 30362 and how does it work?

The primary use of this product is automotive paint refinishing. It's designed to provide scratch-resistant finishes with precise, consistent results. Its unique pyramid structure constantly exposes fresh abrasive particles while maintaining a even finish.

-

How many discs come in each carton and case size of 3M™ Trizact™ Hookit™ Foam Disc 30362 product?

Each carton pack contains fifteen (15) highly useful discs while one case contains four (4) identical cartons.

-

Can I trust that this foam disc will be long-lasting?

Yes, you can rely on its longevity because it uses advanced technology in engineering that produces microreplication at the finest level possible for more prolonged durability than traditional abrasives.

As part of our Perfect-It™ Paint Finishing System, 3M™ Trizact™ Hookit™ Foam Abrasive Discs help reduce the time and material required for compounding, creating significant operating efficiencies during spot and large panel repairs. Trizact™ abrasives remove fine grade sand scratches while staying sharper longer, reducing material costs. In specific situations, the abrasive allows operators to reduce or eliminate additional materials, like wool compounding pads. They can also save time, reducing and even eliminating entire grade sequences such as compounding for more efficient operations. Foam backing provides plenty of control and consistent contact with the surface, great for preserving orange peel. Trizact™ Hookit™ abrasive discs work with Hookit™ disc pads and soft interface pads for responsive application and fast, efficient change outs during the paint finishing process.

Use Trizact™ 3000 grit foam discs for removing 1200-1500 grade sand scratches, and select Trizact™ 5000 grit foam discs for removing 3000 grade sand scratches on painted surfaces. Use with 3M Hookit™ Disc Pad 05551 or 20427 and 3M Hookit™ Soft Interface Pad 05777 prior to the use of 3M™ Perfect-It™ machine polishes and pads.

About Trizact™ AbrasivesFor more predictable finishes and improved, consistent quality, 3M™ Trizact™ products feature 3-dimensional structures that are uniformly distributed over the surface of the abrasive. These patterned, precise mineral structures contain multiple layers of abrasive mineral. As the structures wear, fresh, sharp mineral is exposed. The result is that the abrasive cuts faster, allows for precise finish control, and stays sharper longer – operators can even reduce grade sequences during collision repair, requiring fewer process steps and fewer abrasive products.

About the Hookit™ Attachment SystemThe Hookit™ hook-and-loop feature makes disc attachment, removal, and re-attachment clean and easy, and facilitates use and re-use of the disc for the extent of the abrasive life. Hookit™ disc pads have J-shaped hooks of the type most commonly used in everyday hook-and-loop applications. Hookit™ disc pads grip the brushed nylon loop backings of 3M™ Hookit™ discs and provide a finer finish than do adhesive backed discs. The Hookit™ system is designed for work spaces where adhesive backed discs may become contaminated by dust, dirt, or flying debris.

The Perfect-It™ Brand: 3M's Highest-Quality Solution for Coated SurfacesThe Perfect-It™ brand signifies 3M's most consistently outstanding finish at a minimum of time and expense to obtain a premium like-new appearance. Each 3M™ Perfect-It™ product has been scientifically developed for the highest performance during defect removal, scratch refinement, compounding and polishing. Together, this complete range of products, backed by the technical expertise of 3M, comprises the Perfect-It brand – representing total excellence in preparing and finishing paint and gelcoat surfaces, for each job and for your entire operation.