| SKU | 7000120110 |

|---|---|

| Legacy SKU | 60455067508 |

| UPC | 00076308582074 |

| Catalog Number | 58207 |

| Product Number | 58207 |

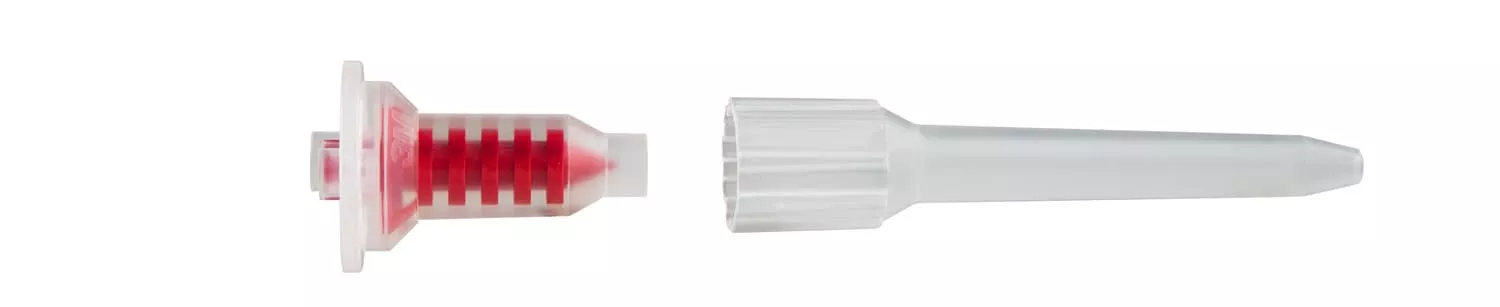

The 3M Dynamic Mixing System Nozzle is integral to fast, accurate mixing of two-part body repair products. Nozzles are specially designed for low-waste mixing that thoroughly blends material to specific ratios. Choose the DMS 1.0 red nozzle for fillers and glazes, and purple nozzles for DMS 1.5 adhesives and sealers. Nozzle extensions are available for adhesives and sealants to reduce bead size.

- Active mixing action thoroughly blends materials for precision mixing every time

- Reduces mess and cleanup – no hand mixing is needed for fillers and glazes

- Short length limits material left inside the nozzle

- Nozzles colored by product line help ensure trouble-free application for adhesives, sealants, fillers and glazes

- Easy clip-on/off application to cartridges saves time

- Nozzle extensions are available to reduce bead size when extruding adhesive and sealants

Product Dimensions |

Imperial | Metric |

| Weight | 0.11883 lbs | |

|---|---|---|

| Width | 3 in | |

| Length | 6 in | |

| Height | 9 in |

Shipping Dimensions |

|

| Weight | 1.05006 lb |

|---|---|

| Length | 8.1248 in |

| Width | 8.1248 in |

| Height | 8.25 in |

| Color | Opaque |

|---|

PRODUCT FAQ

-

What is the 3M™ Dynamic Mixing System Nozzle Extension, 58207?

The 3M™ Dynamic Mixing System Nozzle Extension, 58207 is a specially designed nozzle extension that helps contractors reach difficult spots during application.

-

How many extensions come in each pack and case of it?

Each bag contains 12 pieces of the nozzle extension while there are six bags per case, or a total of 72 pieces.

-

Can this product be used with any applicator gun?

Yes! The nozzle extension can easily fit onto most dynamic mixing system guns available on the market today.

As an integral part of the Dynamic Mixing System, the 3M™ Dynamic Mixing System Nozzle has been designed specifically for dispensing accurately mixed two-part DMS 1.0 and DMS 1.5 products, including epoxies, fillers, glazes, adhesives and sealers in collision repair. These mixing nozzles completely blend materials according to specified mixing ratios, and clip onto cartridges easily. They remove just as easily for maximum efficiency.

3M designed the Dynamic Mixing System Nozzle to make the application of any DMS product more efficient. Choose a red-colored nozzle (05847) for DMS 1.0 products (fillers and glazes). For DMS 1.5 – adhesives and sealers – choose nozzles with the purple color (55847). Nozzle extensions are available for extruding DMS 1.5 products into hard to reach places.

About the 3M™ Dynamic Mixing System for Fillers and GlazesThe Dynamic Mixing System dispenser and mixing nozzles eliminate the need to worry about adding too much or too little hardener to filler and glazes. Dispense products when and where you want them, at the touch of a trigger. There is no messy mixing process, reduced wasted materials, and reduced time for cleaning up. By utilizing the correct amount of product and reducing consumption, you can save both materials and time.

3M™ Dynamic Mixing System: As Easy as Twist, Mix and FixHere is how it works: Twist a cartridge into place on the applicator until it locks into place. For fillers and glazes, attach a red mixing nozzle and mix the two-part component product automatically by simply pulling the trigger on the applicator.

For adhesives and sealers, attach a purple mixing nozzle after equalizing the cartridge. Watch as it mixes and dispenses an accurate ratio of product. Fix, bond or seal instantly by applying the product directly from the applicator to the surface and spread into place.