| SKU | 7000120321 |

|---|---|

| Legacy SKU | 60600148351 |

| UPC | 00051111696729 |

| Product Number | 237AA |

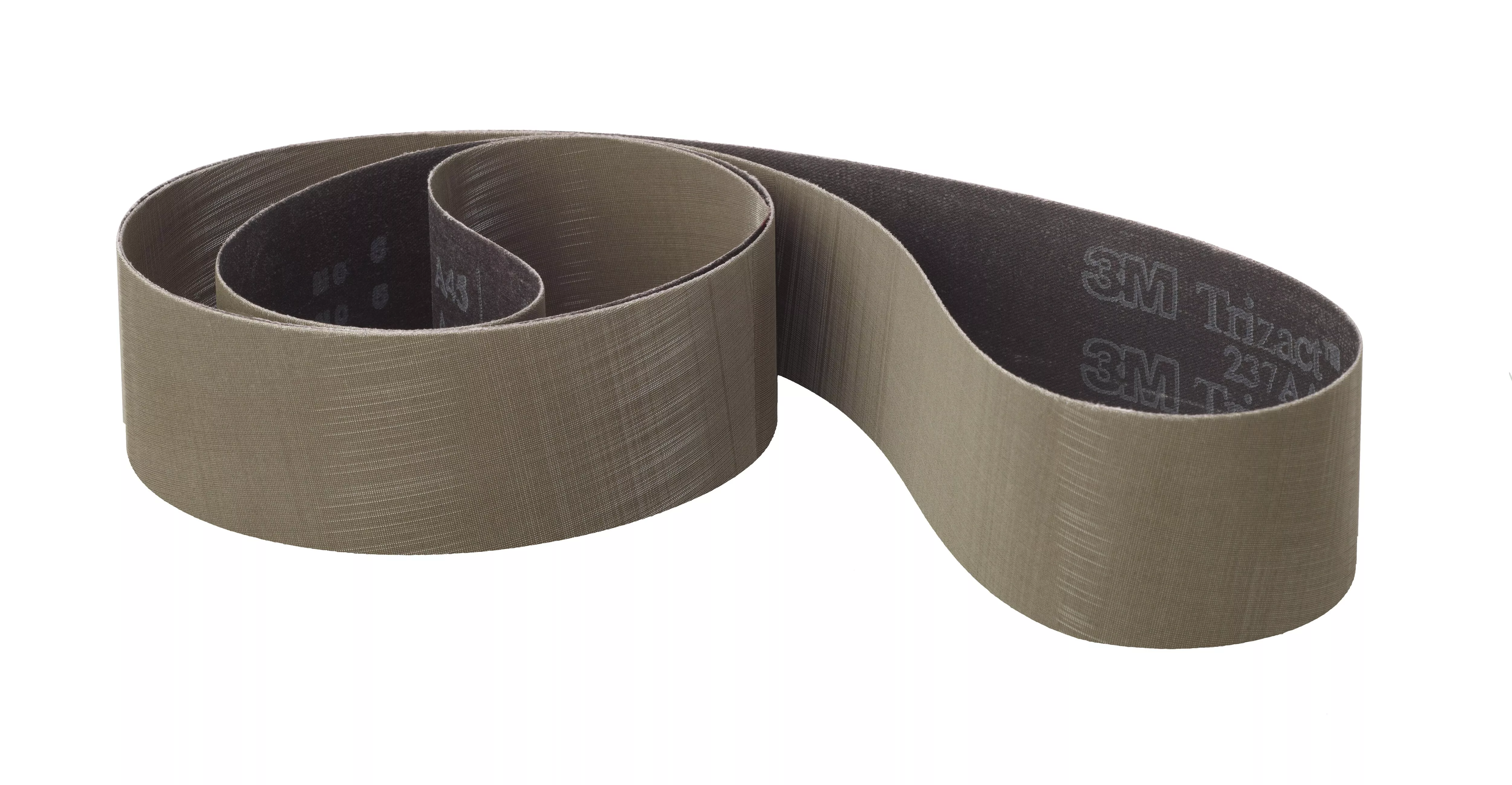

3M Trizact Cloth Belt 237AA uses proprietary microreplication technology by 3M where micron-graded aluminum oxide particles are formed into tiny pyramids of abrasive mineral and then coated on an X weight cloth backing. As these pyramids wear, fresh, sharp mineral is continually exposed to produce a consistent cut and a predictable, fine finish.

- Self-sharpening pyramids start sharp, stay sharp, and run cooler than conventional abrasives

- Flexible backing for consistent finish over contours

- Three-dimensional design enables very consistent finishes throughout the abrasive life in robotic applications

- For intermediate finishing and fine polishing prior to plating or buffing

- Ideal for intermediate finishing and fine polishing prior to plating or buffing

- Produces finer finishes than conventional electrostatically coated abrasives

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 23.25215 lb |

|---|---|

| Length | 14.09449 in |

| Width | 14.01575 in |

| Height | 9.2126 in |

| Color | Gray |

|---|

PRODUCT FAQ

-

What is the 3M™ Trizact™ Cloth Belt 237AA, A100 X-weight, 4 in x 90 in used for?

The 3M™ Trizact™ Cloth Belt 237AA with A100 grit level and a full-flex backing is designed to provide consistent finishes on various materials. It can be used for grinding, cleaning or restoring metals including steel and stainless steel.

-

How long does one belt typically last?

There isn't a specific timeframe for how long the belts last since it depends on factors such as material being processed, pressure applied during use etc. However, these belts are known to maintain their shape longer compared to other abrasive products due their unique construction.

-

Is this product safe to use?

Yes absolutely! These belts have been constructed using high-quality materials that assure safety while using them. We always advise customers to take general precautions when handling any abrasive equipments and wear protective gear like gloves/goggles when needed.

The 3M™ Trizact™ Cloth Belt 237AA is designed to provide consistent finishes on hard metals such as carbon and stainless steel. The abrasive and resin structure is formulated to break down under medium pressure and keep fresh, sharp mineral cutting. The belt also features a grinding aid that helps prevent heat buildup, warping, and discoloration. The X-weight, durable cloth backing helps provide control, conformability, and effective medium-pressure grinding. The resin bonded abrasive gives you greater heat resistance and helps prevent delamination.

Runs Smooth, Finishes ConsistentlyThe belt uses a Film Media Splice, a strong secure bond joining the belt ends, consisting of a thin film-joining media that minimizes "chatter marks," ensures a smooth running belt, and consistent finishing results. Proprietary Trizact™ abrasives produce a finer finish, achieve results faster, and last longer when compared to conventional abrasive products.

Ideal for Robotic Finishing and Polishing3M™ Trizact™ abrasives can consistently deliver near-mirror finishes while also delivering the abrasive life that helps reduce changeouts and downtime in robotic cells. This helps maximize the efficiency of the cell, allowing you to produce more parts per belt. Robotic metal polishing demands the most consistent, refined cut and long abrasive life.

The Science of Flawless Finishes3M™ Trizact™ belts start sharp and stay sharp, resulting in more predictable finishes and improved, consistent quality. They can last up to five times longer than conventional belts and provide precise finish control such that operators can reduce grade sequences, requiring fewer process steps and fewer abrasive products. Three-dimensional structures uniformly distributed over the entire surface of 3M™ Trizact™ abrasives ensure consistent performance and eliminate part to part variation.