| SKU | 7010295256 |

|---|---|

| Legacy SKU | 60990177275 |

| UPC | 00051111510810 |

| Product Number | 264M |

3M Lapping Film Roll 264M is used to create discs, belts and other abrasives designed for flat lapping and finishing on glass, vision wear and fiber optics. It features micron-graded aluminum oxide abrasive grains bonded to a flexible polyester film backing. This fast cutting design produces a fine, uniform finish even on contoured surfaces.

- Used to create abrasives for flat lapping and finishing on glass, vision wear and fiber optic materials

- Micron-graded aluminum oxide abrasive cuts fast and provides a consistent, fine finish

- 3 Mil polyester film backing provides flexibility for consistent finishing on contoured surfaces

- Resin bonding resists deterioration from heat, extending the life of the abrasive cloth

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 117.99802 lb |

|---|---|

| Length | 35.5 in |

| Width | 14.4 in |

| Height | 15.1 in |

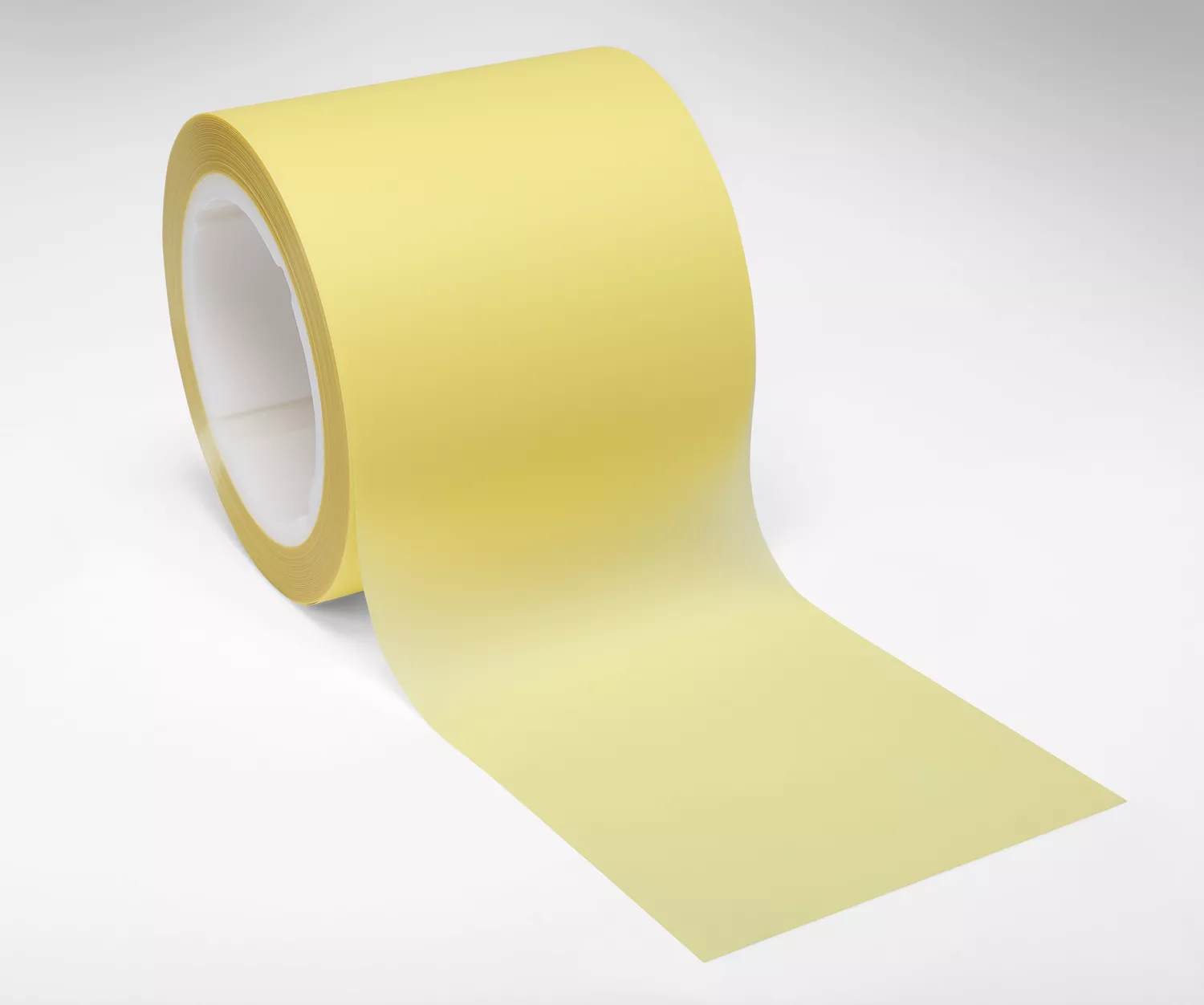

| Color | Yellow |

|---|

PRODUCT FAQ

-

What is the 3M™ Lapping Film Roll 264M made of?

The 3M™ Lapping Film Roll 264M is made of polyester film backing.

-

What does the "12 Mic" mean in the product description?

The "12 Mic" refers to the thickness measurement in microns. In this case, it means that the lapping film roll has a thickness of 12 microns.

-

Is this product suitable for use on all kinds of materials or only specific ones?

This particular type P lapping film roll can be used on a variety of materials ranging from metals and ceramics to glass and plastics.

-

How long is each roll supposed to last before running out?

The length that each roll will last depends largely on how frequently you use it and what kind (and how much) material you're working with. Generally speaking, however, one item should usually suffice for multiple projects before requiring replacement.

-

Is there any recommended storage procedure for these rolls?

For optimal performance over time, we recommend storing our items in cool and dry conditions when not in active use.

Flexible Design

Abrasives made with 3M™ Lapping Film Roll 364M are designed to provide a uniform, consistent finish of optical fiber connectors and end tips to ensure efficient signal transmission. The resin-bonded design supports disc flexibility without sacrificing durability and reliable performance under high heat and pressure. Additionally, the polyester film backing flexes to help achieve a consistent finish over contours and offers greater tear resistance than comparable paper products, making it ideal for high-production environments.

Aluminum Oxide Abrasive

3M™ Lapping Film Roll 264M features precision, micron-graded aluminum oxide, which is a popular choice among industrial professionals because of its fast cut-rate and long useful lifespan. This mineral is a tough, durable abrasive that self-fractures to expose fresh cutting edges, whereas traditional natural abrasives dull more quickly. Due to its fast cut-rate, hardness and strength, it is widely used for a variety of sanding and finishing applications.

Heat Resistant Bonding

The 264M film uses a resin bonding which is specially designed to resist thermal and chemical deterioration, which can occur during lapping and finishing. That heat resistance is especially important when working on sensitive surfaces like glass. The toughness of this type of bond allows for faster sanding at a higher cut rate and makes it excellent for precision work on both hard and soft surfaces.