| SKU | 7010360551 |

|---|---|

| Legacy SKU | 60440199481 |

| UPC | 00051144325580 |

| Product Number | 341D |

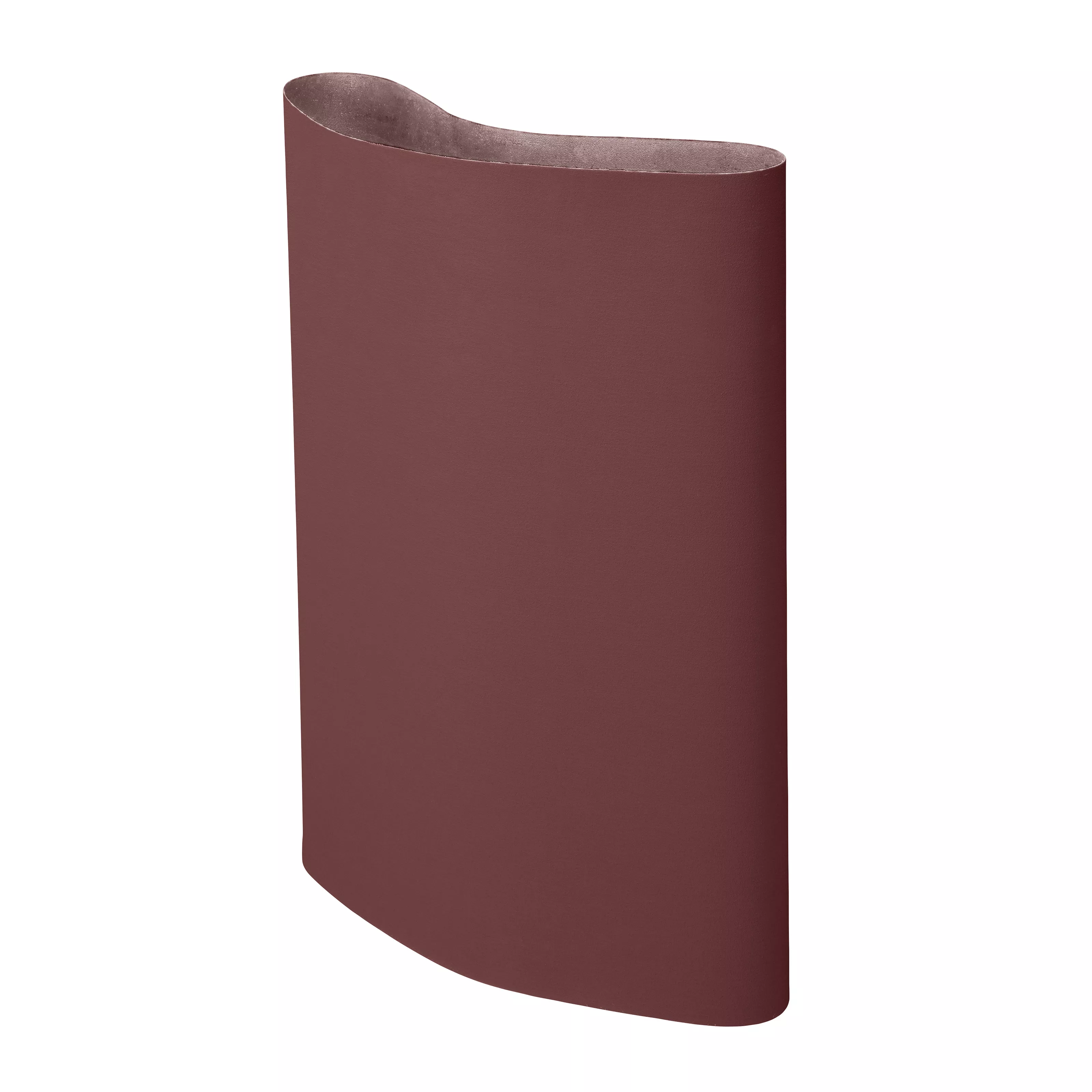

3M Cloth Belt 341D is a durable aluminum oxide cloth belt recommended for your metal deburring, general metalworking, and some woodworking applications. It is suitable for wide belt, edge, or portable belt sanding, and can be used for a variety of applications on metal substrates and wood.

- Tube-shaped band fits inner and outer contours to remove parting lines, imperfections, and burrs

- X-weight cloth backing withstands heavy sanding and grinding

- Resin bond withstands high heat and pressure

- Tough aluminum oxide abrasive mineral cuts fast and performs well on many substrates

- Bands fit onto a rubber expander wheel attachment (sold separately) for use with a die grinder or rotary drill

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 19.99813 lb |

|---|---|

| Length | 40.3748 in |

| Width | 11.8748 in |

| Height | 8.3748 in |

| Color | Brown |

|---|

PRODUCT FAQ

-

What type of material is the 3M Cloth Belt 341D made from?

The 3M Cloth Belt 341D is made from a durable aluminum-oxide abrasive grain, which provides excellent cut-rate and longevity.

-

How large is the belt and how does it attach to my machine?

The belt measures at 37 inches by 75 inches and uses Film-lok technology for easy attachment onto your sanding machine.

-

Can I use this on hardwood floors without damaging them?

Yes! This cloth belt has been specifically designed to be used on various surfaces including hardwood floors while providing an aggressive cutting power with flexibility that conforms well to contours.

-

. How long will each belt last before requiring replacement?

. Time varies based on usage, but we are confident you'll get plenty of life out of your purchase as these belts have been known for their extended lifespan due to its X-weight cloth backing.