| SKU | 7010363438 |

|---|---|

| Legacy SKU | 60600131118 |

| UPC | 00051111678114 |

| Product Number | 747D |

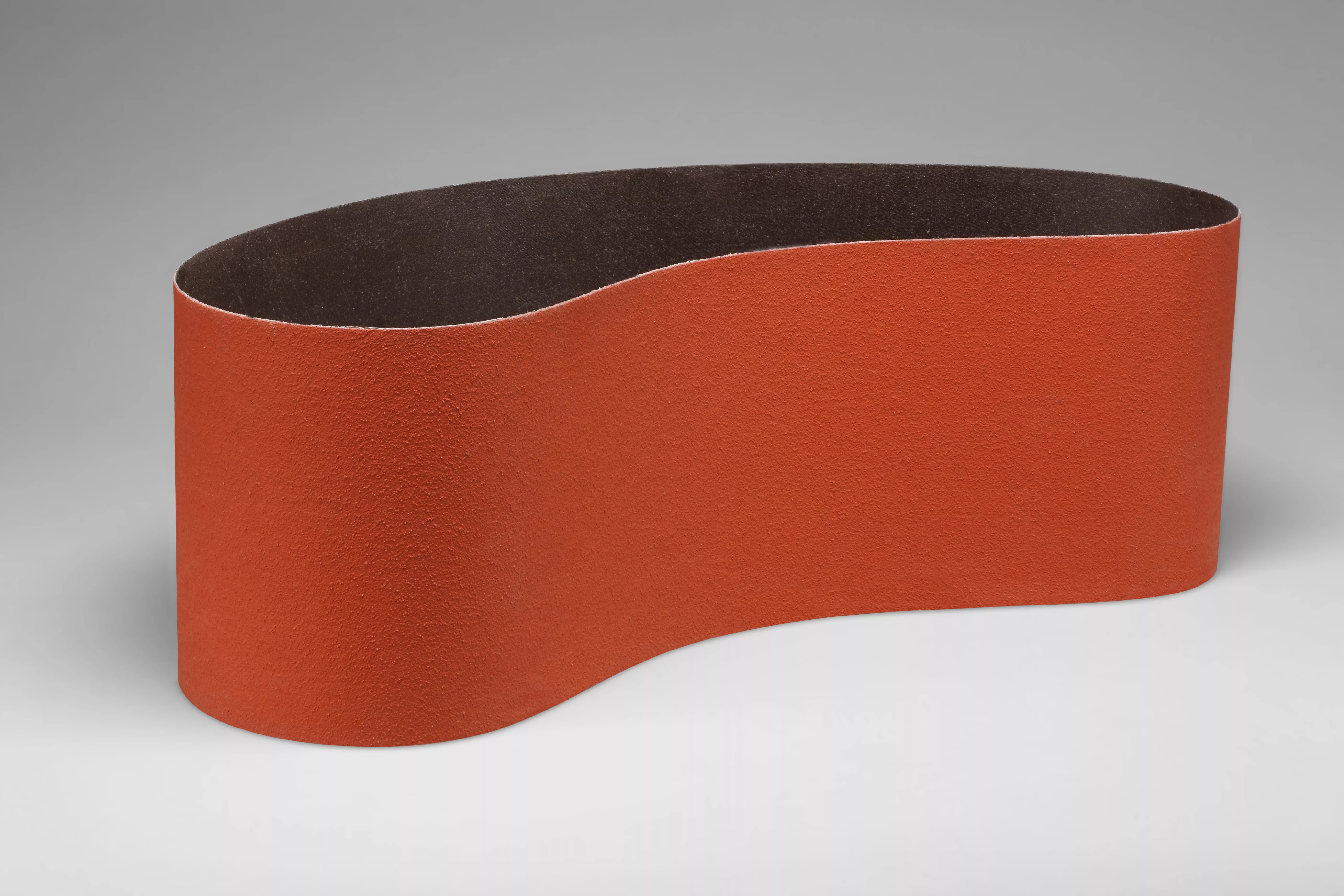

3M Cloth Belt 747D is made with a blend of aluminum oxide and 3M ceramic grain and is designed for superior metal finishing on a variety of metals including nickel and stainless steel.

- Excellent belt for stroke sanding on many metals including stainless steel

- Anti-friction backing helps abrasive run smooth

- X-weight cotton backing withstands aggressive sanding and grinding

- Grinding aid helps reduce heat and grinding temperatures

- Delivers exceptional finishes on a variety of metal substrates

- Ceramic aluminum oxide blend offers excellent cut rate and life for better performance

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 32.47696 lb |

|---|---|

| Length | 14.09449 in |

| Width | 14.01575 in |

| Height | 13.50394 in |

| Color | Orange |

|---|

PRODUCT FAQ

-

What type of abrasive material is used in the 3M™ Cloth Belt 747D?

The abrasive material that is used in our 3M™ Cloth Belt 747D P120 X-weight model is aluminum oxide.

-

Is this cloth belt sturdy for heavy-duty metal finishing projects?

Yes, it's ideal for heavy-duty metalworking applications because of its durability and long-lasting ability. It can work on a range of metals including carbon steel, stainless steel, titanium and more.

-

:What is Film-lok backing technology?

This backing technology secures an abrasive disc to a backup pad without using any adhesive or fasteners. And It makes changing discs simple as they can be peeled off easily.

-

: How many belts come inside one case?

A total of twenty (20) cloth belts are supplied per case with dimensions of 6 inches width by 202 inches length each.

3M™ Cloth Belt 747D is designed with an anti-friction coating that reduces premature wear of stationary platens that remain static while grinding. This feature, combined with the semi-flexible X weight backing, makes Cloth Belt 747D an ideal choice for projects that require a durable and malleable abrasive. Additionally, the grinding aid on Cloth Belt 747D is an added coating that helps the abrasive stay cool during grinding, minimizing heat and improving abrasive performance.

Blended Ceramic GrainsCloth Belt 747D is engineered using 3M™ ceramic materials, which enhance the toughness and hardness of the grain. Ceramic blend products feature aluminum oxide blended with ceramic grain for a harder, longer-lasting abrasive. Ceramic abrasives are perfect for stock removal, as they are engineered to fracture frequently for a super-fast cut and can handle intense heat and stress applications. The ceramic/aluminum oxide blend surpasses aluminum oxide abrasives in cut-rate and durability, making the 3M™ Cloth Belt 747D an excellent choice for moderate stock removal and surface preparation.

- Anti-friction coating reduces premature wear of stationary platens

- Semi-flexible X weight backing for durability and malleability

- Grinding aid helps abrasive stay cool during grinding

- 3M™ ceramic materials enhance toughness and hardness of the grain

- Ceramic blend products feature aluminum oxide blended with ceramic grain for a harder, longer-lasting abrasive

- Ceramic abrasives are perfect for stock removal and can handle intense heat and stress applications

- Ceramic/aluminum oxide blend surpasses aluminum oxide abrasives in cut-rate and durability