| SKU | 7010366278 |

|---|---|

| Legacy SKU | 61500140712 |

| UPC | 00048011243979 |

| Product Number | SC-RL |

Scotch-Brite Surface Conditioning Roll effectively blends, deburrs, finishes and cleans a variety of substrates. It can also be used for light grinding. The versatility of the Scotch-Brite Surface Conditioning Roll makes it a good all-purpose product.

- Available in a variety of sizes and grades to meet various project requirements

- Color coded by grade to reduce risk for error

- Works well on metal, plastics and composites

- Open web responds to surface irregularities while minimizing the geometry alteration on the part

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 10.99886 lb |

|---|---|

| Length | 12.59961 in |

| Width | 12.5 in |

| Height | 13.3 in |

| Color | Blue |

|---|

PRODUCT FAQ

-

What is the Scotch-Brite™ Surface Conditioning Roll, SC-RL, A/O Very Fine made of?

The Scotch-Brite™ Surface Conditioning Roll, SC-RL, A/O Very Fine material is made of aluminum oxide minerals.

-

Is the 12" x 30 ft dimension the only size available for this product?

No. While a single roll measures 12 inches by 30 feet per case, it is available in various sizes to fit multiple needs and applications.

-

Can I use this on any surface type or are there specific materials that would not work well with this conditioning roll?

Our very fine abrasive mineral allows you to refine and finish on virtually all metals for dimensional stability and long service life. It can also be used dry or with water or oil lubricating fluids as needed.

The Scotch-Brite™ Surface Conditioning Roll offers a range of benefits that operators have come to expect from Scotch-Brite™ products. This includes nonwoven abrasive technology and a consistent cut. The product is available in aluminum oxide or silicon carbide mineral, as well as a range of grades from super fine (SFN) to coarse (CRS). Depending on the grade, the Scotch-Brite™ Surface Conditioning Roll can cut less aggressively and produce a finer finish or cut more aggressively and produce a coarser finish. With a variety of grades and minerals available, operators can find the product that best suits their specific project needs.

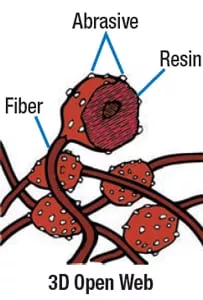

What makes Scotch-Brite™ abrasives unique is their nonwoven technology. Abrasive mineral is interspersed on synthetic fibers using resin, creating an open web construction. This design allows excess material to escape, preventing the mineral from getting worn down by debris. As a result, the mineral stays sharper longer, enhancing cut performance and increasing abrasive service life. The spring-like nature of the fibers works well on contours and responds to subtleties on the surface. The responsive design effectively removes unwanted burrs, soils, and contaminants without ruining the base material, ensuring a consistent and uniform finish – part after part.