| SKU | 7100076727 |

|---|---|

| Legacy SKU | 62329335301 |

| UPC | 00021200878459 |

| Catalog Number | 125 |

| Product Number | DP125 |

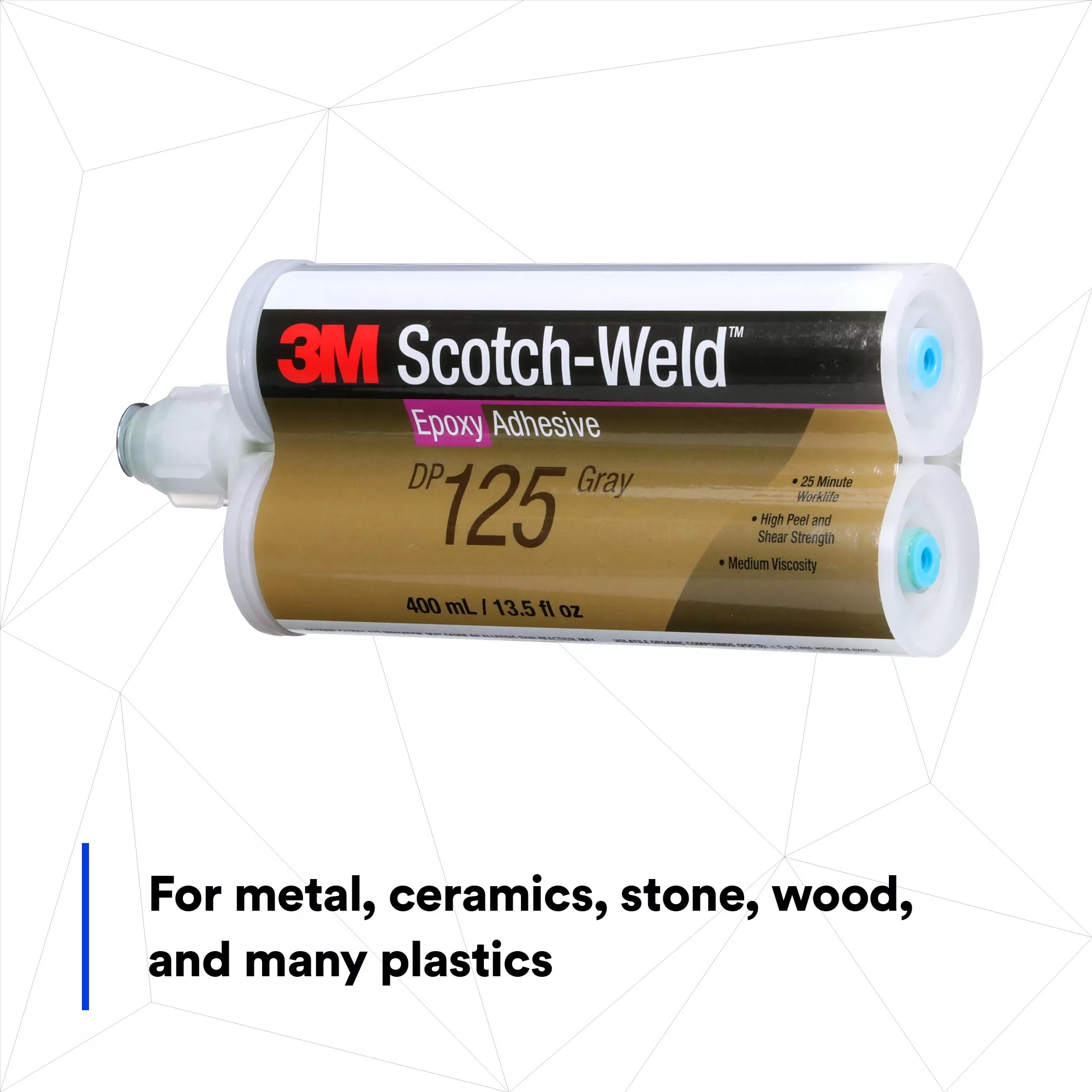

3M Scotch-Weld Epoxy Adhesive DP125 is a low odor, two-part epoxy structural adhesive that creates strong and flexible bonds on metal, ceramics and many plastics where coefficients of thermal expansion are a consideration. This versatile adhesive can be used in joining, gluing and structural bonding in appliance, general industrial, transportation and signage segments. It applies easily and flows smoothly for controlled dispensing that minimizes dripping, running and migration. The 1:1 mix ratio is ideal fo

- BONDS A VARIETY OF SUBSTRATES: Bonds metal, various plastics, ceramics, stone and dissimilar surfaces where coefficients of thermal expansion are a consideration

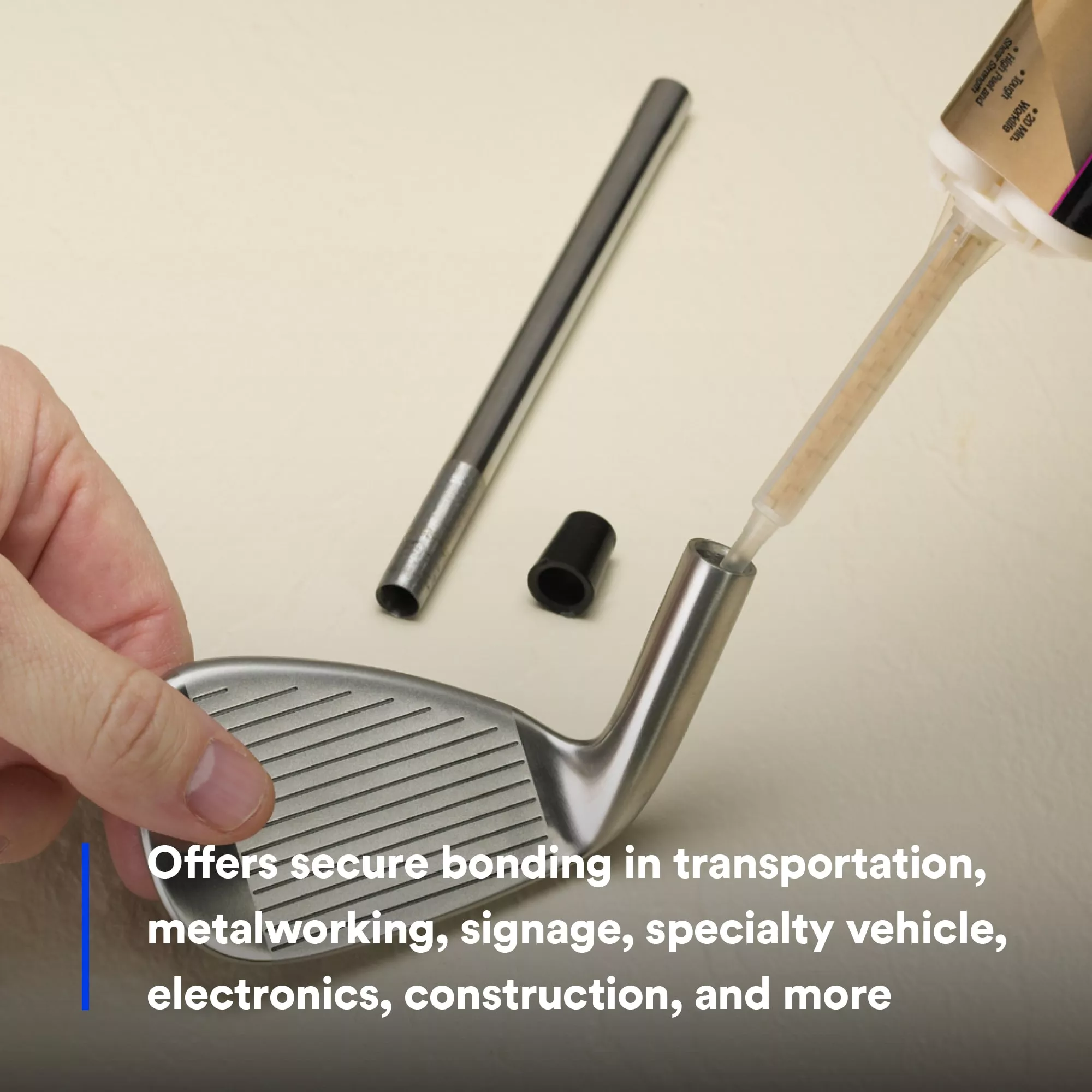

- MULTIPLE APPLICATIONS AND MARKETS: Can be used in joining, gluing and structural bonding in appliance, general industrial, transportation and signage segments, as well as a host of other applications

- ENHANCED VIBRATION RESISTANCE: Flexible when cured, this epoxy is excellent for bonding dissimilar surfaces where resistance to flexing, vibration and other stresses is needed

- THERMAL EXPANSION TOLERANT: Maintains a strong bond under expansion, contraction and limited movement

- CONTROLLED FLOW: Medium viscosity helps minimize running, dripping and migration

- QUICK SET TIME: Features a 25 minute working time, reaching handling strength in approximately 150 minutes at room temperature

Product Dimensions |

Imperial | Metric |

| Weight | 1.336 lbs | |

|---|---|---|

| Width | 3.62598 in | |

| Length | 1.8752 in | |

| Height | 9 in |

Shipping Dimensions |

|

| Weight | 8.54071 lb |

|---|---|

| Length | 8.07087 in |

| Width | 6.1811 in |

| Height | 9.88189 in |

PRODUCT FAQ

-

What is 3M Scotch-Weld Epoxy Adhesive DP125?

3M Scotch-Weld Epoxy Adhesive DP125 is a two-part epoxy adhesive that provides excellent bonding properties for a wide range of industrial applications.

-

How much product does each package contain?

Each unit contains 400 mL of gray, two-part adhesive that comes in the form of a Duo-pak with an easy-to-use applicator.

-

Can this adhesive be used on different types of materials?

Yes! This versatile product bonds well to many different surfaces, including metal, wood, ceramics and most plastics.

-

What are some benefits to using this specific type of epoxy adhesive over competitors’ products?

As compared to other traditional adhesives, this high-performance formula offers incredibly fast cure times which can lead to increased efficiency in the manufacturing process. It also has great resistance against chemicals and heat exposure over time.

-

Q: How should I use 3M Scotch-Weld Epoxy Adhesive DP125?

A : To apply just mix one part base with one part accelerator by volume using supplied mixing nozzle then squeeze trigger gradually until mixed thoroughly appears.Apply it always after cleaning your surface before handling so you get maximum bond strength after curing completely depending upon environmental factors such as temperature and humidity; it usually takes only about five minutes after application while holding parts tightly together until cured properly- either up to room temperature or within its allowable working window which typically lasts anywhere between ten and sixty minutes depending on how much hardener has been used upfront

When using a Duo-Pak (DP) size adhesive, rely on 3M dispensing equipment for convenient and accurate metering, mixing and dispensing. Our 3M™ Scotch-Weld™ Epoxy Adhesive DP125 is a versatile, medium viscosity, epoxy adhesive that pours easily with minimal dripping, running and migration that will flow smoothly for a controlled, accurate dispensing. Its flexibility makes it ideal for applications involving dissimilar surfaces, where coefficients of thermal expansion are a consideration, for example when bonding glass to metals.

Recommended Applications- General attachment applications in a variety of industries

- Replace 5 minute epoxy for improved performance and more positioning time

The 1:1 mix ratio for our 3M™ Scotch-Weld™ Epoxy Adhesive DP125 is ideal with bulk mixing and with a 25-minute work life there's some opportunity for repositioning to keep projects on track. The adhesive reaches handling strength in approximately 150 minutes and is fully cured in 7 days (at 72°F/22°C).

Understanding Epoxy AdhesivesEpoxy adhesives are part of the class of adhesives called "structural adhesives," which include polyurethane, acrylic, cyanoacrylate and others. Epoxies are formulated as liquid reactive polymers that undergo a chemical reaction when mixed and then cure to form a solid plastic material. Once the two parts are mixed in their specified ratio, they begin the curing process and offer a limited working time where the adhesive can be applied and the two surfaces positioned as needed. This work life lasts anywhere from a few minutes to several hours. These structural adhesives provide high shear and peel strengths, depending on the formula, and better heat and chemical resistance than other common adhesives. In general, epoxy adhesives have the highest overall strength and offer the best performance and most resistance to high temperatures, solvents and outdoor weathering.

Epoxy adhesive (often referred to as epoxy glue) is widely used in building and home construction; aircraft and automobile manufacturing; bicycle, boat, golf clubs, ski and snowboard assembly as well as a host of home use and other applications. It is used virtually anywhere high-strength bonds are needed along with resistance to environmental conditions. These adhesives are popular for their ease of use, mechanical strength and chemical resistance. Formulations can be created to make epoxy for plastic flexible or epoxy for metal rigid, epoxy resin transparent or opaque, quick setting or slow setting. The versatility with which these adhesives can be formulated helps meet almost any requirement for bonding wood, metal, glass, stone and various plastics.