| SKU | 7100094063 |

|---|---|

| Legacy SKU | 60440305526 |

| UPC | 00076308643164 |

| Product Number | 64316 |

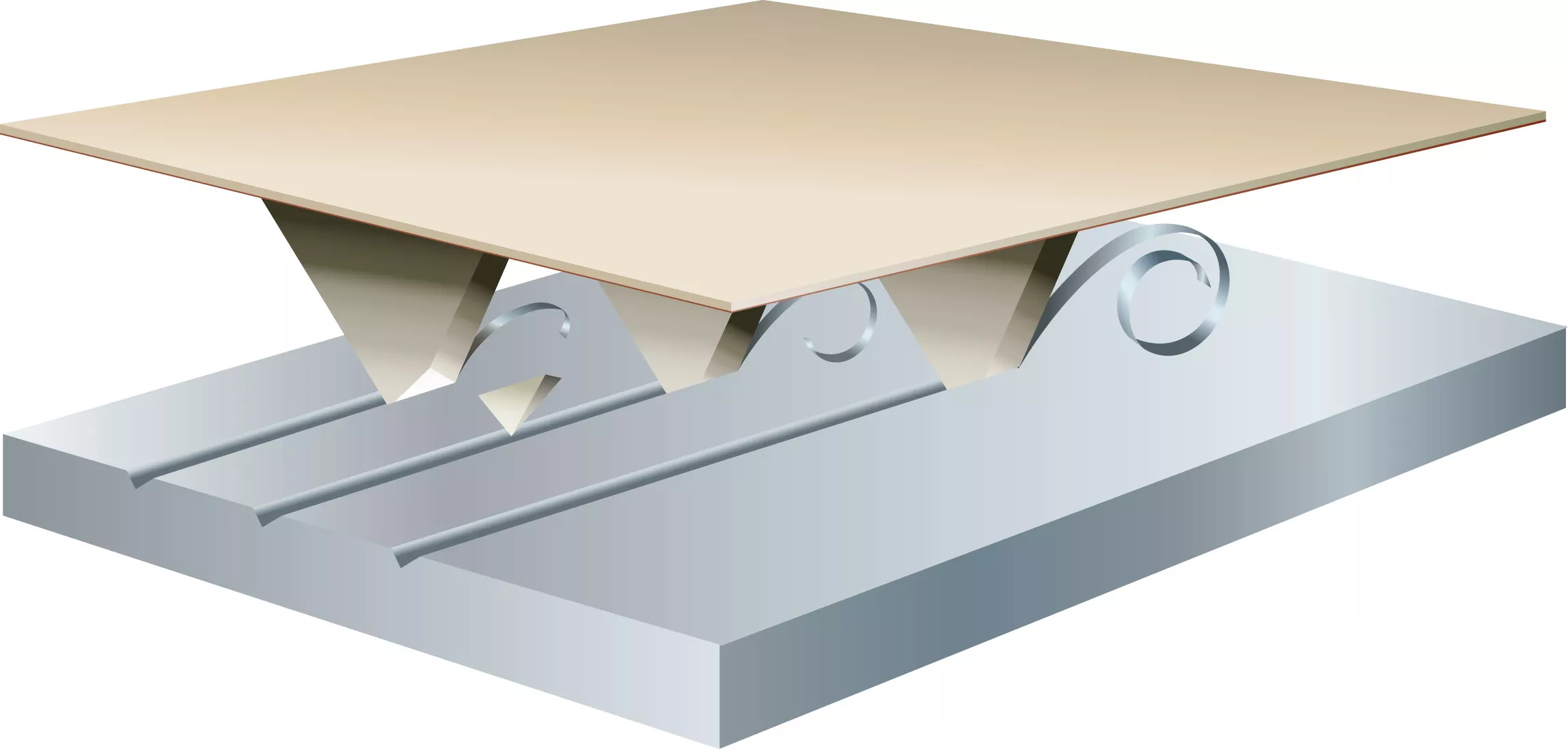

3M Cubitron II Grinding Wheel is constructed of 3M precision-shaped ceramic grain to bring you an exceptionally fast-cutting and long-lasting rigid bonded wheel for heavy weld removal and other heavy-duty grinding applications. This grinding wheel works well on almost all materials and is specially formulated for use on stainless steel, mild steel, and aerospace alloys.

- 3M Precision-shaped grain engineered to cut faster than competitive ceramic products, offering significant productivity gains

- Triangular shaped ceramic grain wears evenly, runs cool, and optimizes mineral breakdown, for extra-long life

- Reduces changeouts and downtime in robotic and pressure-assisted applications

- Rigid, reinforced resin-bonded wheel slices through almost all materials including stainless steel, mild steel, and aerospace alloys

- Wheel must have a maximum operating speed greater than or equal to the maximum speed of the power tool used

- Must be used with ANSI-approved guard that fits the size of the wheel

Product Dimensions |

Imperial | Metric |

| Weight | 1.60717 lbs | |

|---|---|---|

| Width | 9 in | |

| Length | 1/4 in | |

| Height | 9 in | |

| Diameter | 9 in | 230 mm |

| Thickness | 1/4 in | 6 mm |

| Center Hole Diameter | 7/8 in | 22.23 mm |

Shipping Dimensions |

|

| Weight | 32.3901 lb |

|---|---|

| Length | 9.88189 in |

| Width | 9.88189 in |

| Height | 8.30709 in |

| Color | Black |

|---|---|

| Maximum Speed | 80 m/s |

| Grit | 36+ |

PRODUCT FAQ

-

What materials is the 3M™ Cubitron™ II Depressed Center Grinding Wheel designed for?

The Cubitron II grinding wheel is specifically designed to grind and cut through hard metals like stainless steel, mild steel, and cast iron.

-

How long does the 3M™ Cubitron™ II Depressed Center Grinding Wheel last?

This product features advanced abrasive technology that allows it to last longer than conventional grinding wheels. Its lifespan will depend on factors such as material hardness, operator technique, and pressure applied during use.

-

What size is the center hole of this grinding wheel?

The center hole diameter on this particular model is 7/8 inches.

-

Can you tell me more about the packaging options for this product?

The 3M™ Cubitron™ II Depressed Center Grinding Wheels come in packs of ten if you’re just looking for a few or twenty-five if you need them in bulk. Each individual blister pack ensures high-quality storage and protection - but we can always accomodate custom orders upon request!

3M™ Cubitron™ II Depressed Center Grinding Wheel is designed to exceed the performance of other grinding wheels in both cut and life, resulting in significant gains in productivity. The power of 3M Precision-Shaped Grain provides a cool, extra-sharp, quick cut that lasts longer than other wheels.

Ideal for Robotic Weld GrindingFor medium and high-pressure applications like robotic weld grinding, it is crucial to choose a high-performance abrasive that cuts fast and lasts long. The self-fracturing mineral in 3M™ Cubitron™ II Depressed Center Grinding Wheel ensures that your robot can grind welds for a longer time, reducing downtime and maximizing efficiency.

Grinding Wheel: Tips for Optimum UseA grinding wheel is a rigid resin-bonded wheel that is approximately 1/4" thick and is useful for removing welds from internal angles. Fiber discs are typically better for grinding welds on flat surfaces. A grinding wheel must be used with a right angle grinder that has a wheel guard designed for the size of the wheel used. Type 27 wheels have a depressed center that allows grinding at any angle without damaging the surrounding surface. The grinding wheel must have a maximum operating speed greater than or equal to the maximum speed of the grinder used.

3M Precision-Shaped Grain Maximizes Cutting Potential3M™ Cubitron™ II products have set a new standard for high-performing abrasives. 3M engineers used proprietary precision-shaped grain technology to maximize cutting potential, starting with 3M™ ceramic abrasive grain. Precision-shaped grain fractures into super-sharp points and edges that slice cleanly through metal, rather than plowing like traditional abrasives, ensuring extended high performance in heavy-duty production applications. The grains wear evenly and provide extra-long life and consistency with less grinding pressure. 3M™ Cubitron™ II abrasives outcut and outlast competitive ceramic abrasives, maximizing productivity and minimizing operator fatigue.