| SKU | 7100141915 |

|---|---|

| Legacy SKU | 61500034766 |

| UPC | 00048011058665 |

| Product Number | CP-DC |

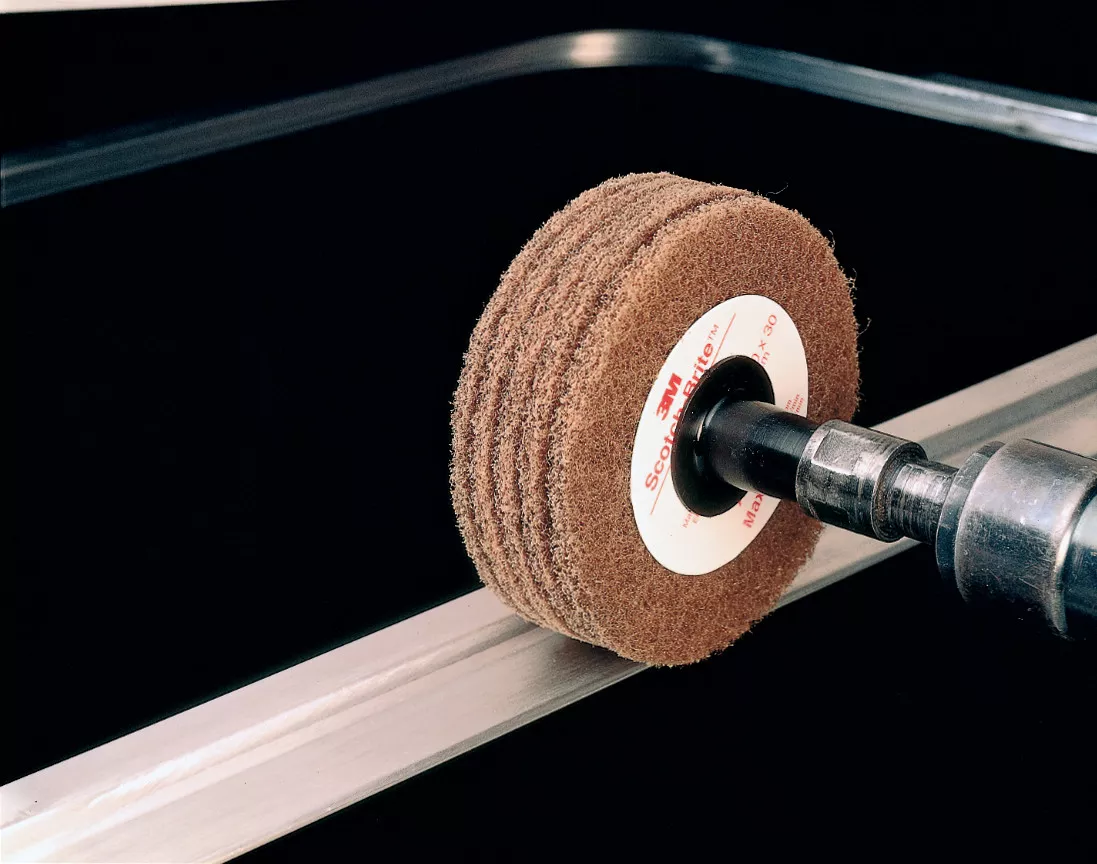

Scotch-Brite Cut and Polish Disc is engineered to produce satin or high-luster finishes and may be used for cleaning or light deburring on a variety of metals. The durable open-web construction is designed to resist loading and greatly increase the life of the disc.

- Aluminum oxide mineral delivers an aggressive cut with a polished surface

- Durable non-woven web construction resists loading, prolonging service life of the disc

- Ideal for aggressive blending and finishing

- Versatile disc may be used on bench motor or straight shaft tool

- Provides high cut-rate and low heat retention, allowing extended contact with the workpiece

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 4 in | 101.6 mm |

| Center Hole Diameter | 6.35 mm |

Shipping Dimensions |

|

| Weight | 5.00008 lb |

|---|---|

| Length | 12.5 in |

| Width | 12.5 in |

| Height | 7 in |

| Color | Tan |

|---|---|

| Thread Size | Non Pertinent |

| Maximum Speed | 6,000 rpm |

PRODUCT FAQ

-

What is the size of the CP-DC, A/O Medium, 4 in x 1/4 in, 150 ea/Case?

The diameter of the Cut and Polish Disc is 4 inches and its center hole measures about a quarter inch. Each box case contains 150 individual discs.

-

How does CP-DC work when cutting or polishing metal surfaces?

Our CP-DC abrasives use aluminum oxide grit particles that are bonded to non-woven synthetic fibers. This makes them an ideal tool for blending and finishing all different kinds of metals including steel, iron, brass copper and stainless steel surfaces with superior performance.

-

Are there any specific precautions I should take whenever using these abrasive products?

When dealing with cut-off wheels or similar abrasives like our Scotch-Brite™ Cut & Polish Discs it's crucial to wear eye protection along with gloves since shattered bits could fly right into your face causing injury. Additionally, make sure you read the user manual before usage to ensure proper safety procedures are followed at all times.

-

Can these discs be reused after their initial application?

Unfortunately not as re-using manufactured consumables such as worn down scotch-brite™cutting wheels won't only lead to poor results but also create safety risks. So we guarantee that every disc included in each box capable of giving you quality finish till it reaches its ultimate shelf life which may vary based on storage conditions/home environment (generally around two years from production date).

Scotch-Brite™ Cut and Polish Disc was designed with aluminum oxide mineral, which is a popular mineral choice among industrial professionals because of its fast cut-rate and long life. This mineral creates a tough, durable abrasive that self-fractures to expose fresh cutting edges, while traditional natural abrasives dull more quickly. This makes it suitable for a wide variety of materials in both woodworking and metalworking, including ferrous alloys. Due to its fast cut-rate, hardness, and strength, it is widely used in grinding applications in addition to sanding and finishing applications.

Scotch-Brite™ industrial abrasives are a unique surface conditioning product with abrasives incorporated into non-woven nylon or other synthetic fibers. By combining abrasives into the fibers, an abrasive system is created that delivers consistent results for the life of the product. The open-web material is load resistant and keeps the abrasive minerals cutting at high performance by limiting clogging of the fibers.