| SKU | 7100190572 |

|---|---|

| Legacy SKU | 60440319378 |

| UPC | 00638060380611 |

| Catalog Number | 7100190572 |

| Product Number | 747D |

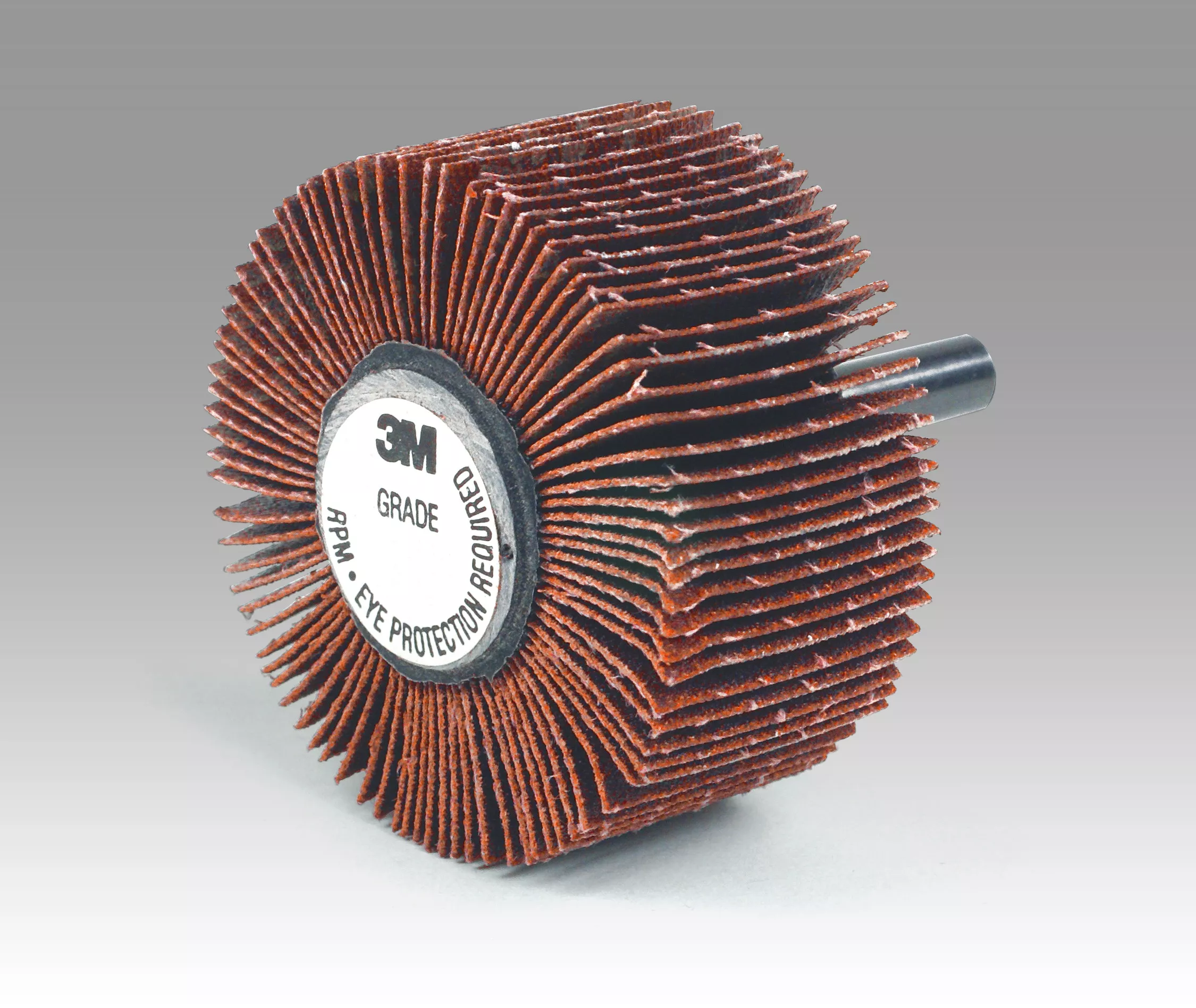

3M Flap Wheel 747D was designed for light grinding, blending, deburring, and polishing on a variety of metals. Ceramic abrasive covered flaps conform to the work piece and provide a smooth clean finish.

- Ceramic aluminum oxide blend offers excellent cut rate and life for better performance

- X-weight cotton backing withstands aggressive sanding and grinding

- Resin bonding resists thermal and chemical deterioration for extended wheel life

- Abrasive flap design provides a soft and smooth cut on rounded or irregular surfaces

- Includes a grind-aid to provide cooler running on stainless-steel and other metals

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 1-1/2 in | 38.1 mm |

| Center Hole Diameter | 1/4 in | 6.35 mm |

Shipping Dimensions |

|

| Weight | 0.961 lb |

|---|---|

| Length | 7.12598 in |

| Width | 5.11811 in |

| Height | 5 in |

PRODUCT FAQ

-

What is the 3M Flap Wheel 747D used for?

The 3M™ Flap Wheel 747D is commonly used for blending, finishing contours and curves, cleaning welds or removing rust, scale and coatings.

-

What size is the flap wheel and how many are in a case?

This specific flap wheel comes in the size of 1-1/2 inches x 1 inch x 1/4 inch with P120 X-weight. Each case contains ten units of this product.

-

Is it compatible with any particular kind of tool or machine?

Yes, this product has a universal fit that can be used on bench motors as well as hand-held tools like drills to allow quick changeovers without using special tools required by integral shank arbors.

-

How does it compare to other flap wheels available in terms of durability?

The abrasive cloth that makes up the flaps resists wear while maintaining consistent cutting action throughout its life. You may find exceptional results from other models too based on your requirements but there's no doubt about D7 model being one of our best ones!

The 3M™ Flap Wheel 747D is a high-performance abrasive wheel that features a ceramic abrasive mix on each flap. This mix was created using a proprietary process that enhances the toughness and hardness of the grain. The ceramic abrasive mix is a blend of aluminum oxide and 3M ceramic grain, which creates a harder and longer-lasting abrasive. Ceramic abrasives are engineered to cut fast and handle intense heat and stress applications, making them perfect for light to moderate stock removal.

The ceramic/aluminum oxide blend surpasses aluminum oxide abrasives in cut-rate and durability, making it an excellent choice for moderate stock removal and surface preparation.

High Quality ConstructionThe abrasive mix is attached to a flexible cotton backing using a resin bond. This resin bonding material is specially designed to resist thermal and chemical deterioration that can occur during high-speed sanding. The bond is very hard, allowing for faster cuts and a higher cut rate. The wheel also includes a grinding aid for cooler running on stainless steel.

Each flap uses an X-weight cotton backing, which provides a tough but flexible surface that bends to fit any workpiece. As the wheel is used, the self-cutting flaps wear away to expose sharp, new abrasive material, ensuring that surfaces are sanded consistently throughout the life of the wheel.

Flap Wheel AdvantagesCoated abrasive flap wheels are the ideal choice for light grinding, blending, graining, and scale removal on a variety of metals. The abrasive flaps offer a long-lasting supply of fresh abrasives and a load-resistant design. 3M™ flap wheels are available in both flange-mounted and spindle-mounted constructions with general-purpose aluminum oxide or high-performing 3M ceramic aluminum oxide blend abrasive grain.

- Long-lasting supply of fresh abrasives

- Load-resistant design

- Available in flange-mounted and spindle-mounted constructions

- General-purpose aluminum oxide or high-performing 3M ceramic aluminum oxide blend abrasive grain