| SKU | 7100207284 |

|---|---|

| Legacy SKU | 70007540373 |

| UPC | 00638060403792 |

| Catalog Number | 8985L |

| Product Number | 8985L |

3M Anodization Masking Tape 8985L is a reliable non-silicone solution for Type I (chromic acid) anodization. Designed for performance, it is specifically resistant to chromic acid and provides sharp lines with a rubber adhesive for easy removal. This tape can mask and de-mask up to 5x faster* than labor-intensive liquid masking for improved productivity.

- Designed specifically for masking in chromic acid (Type I) anodization baths

- Masks and de-masks up to 5x faster* than liquid masking, with no cure time

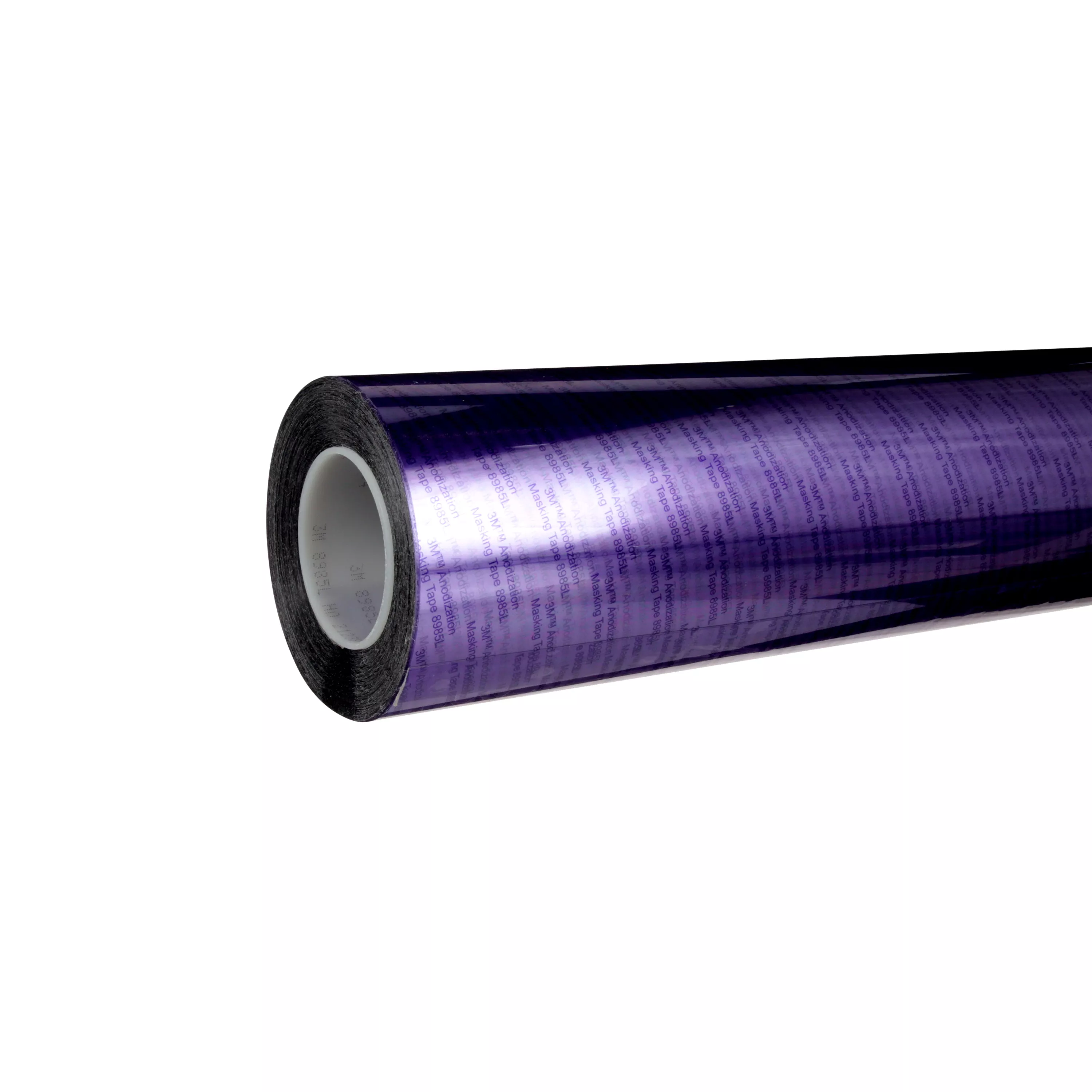

- Transparent purple tape for fast, accurate positioning and easy identification

- Provides sharp masking lines and minimizes leaking to reduce the need for part rework

- Non-silicone formulation helps reduce post-process coating and bonding failures

- Polyester backing with rubber adhesive and film liner

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Thickness | 3.9 mil | 0.1 mm |

Shipping Dimensions |

|

| Weight | 38.58101 lb |

|---|---|

| Length | 11.4 in |

| Width | 11.4 in |

| Height | 14.3 in |

| Color | Purple |

|---|

PRODUCT FAQ

-

What is 3M™ Anodization Masking Tape 8985L used for?

3M™ Anodization Masking Tape 8985L is specifically designed to provide clean removal during masking operations involving aluminum anodized surfaces. It has a typical application time of up to six months, which helps improve productivity and reduce cleanup.

-

Is the tape resistant to harsh chemicals?

Yes! This purple-colored tape features excellent chemical resistance, making it ideal for use in the most demanding applications. Whether you’re working with anodizing baths, plating tanks or other industrial processes that require superior protection against harsh chemicals.

-

How long can I leave this tape on my project?

You’ll be able to remove this tape cleanly after processing without leaving adhesive residue up to six months after application when exposed to indirect sunlight, ranging from -60°F (-50°C) minimum exposure temperature & +350°F (+177°C) maximum exposure temperature.

3M™ Anodization Masking Tape 8985L is designed to withstand chromic acid anodization baths (Type I anodization) with its tough polyester carrier. It also features a non-silicone rubber adhesive to prevent silicone contamination that could affect downstream processes such as bonding or paint adhesion. This tape provides sharp masking edges, minimizing leakage and the need for rework, and can be used with or without chemical film on a variety of aluminum and other metal alloys.

3M™ Anodization Masking Tape 8985L is a transparent tape that can replace complex, messy liquid masking and the unpleasant odors involved. It is easy to position and can be applied in fewer steps, eliminating the cure time of a liquid so that overall masking and de-masking can be accomplished up to five times faster*. The tape's ease of application and clean, one-piece removal can save users up to 60%* on labor time and associated costs. It is transparent purple with a printed backing for visibility and has a liner for easy die-cutting.

*Up to 5x faster and up to 60% reduction in labor time both based on 3M internal data.

Recommended Applications- Aerospace components

- Precision machine components

- Welded assemblies

The 3M Industrial Adhesives and Tapes Division uses the science of adhesion to provide innovative solutions that enhance the design and manufacturing processes of companies worldwide. Ultimately, these technologies help customers deliver competitive products to the market faster and more efficiently.