| SKU | 7100265579 |

|---|---|

| Legacy SKU | 60440409294 |

| UPC | 00638060894026 |

| Product Number | 347FC |

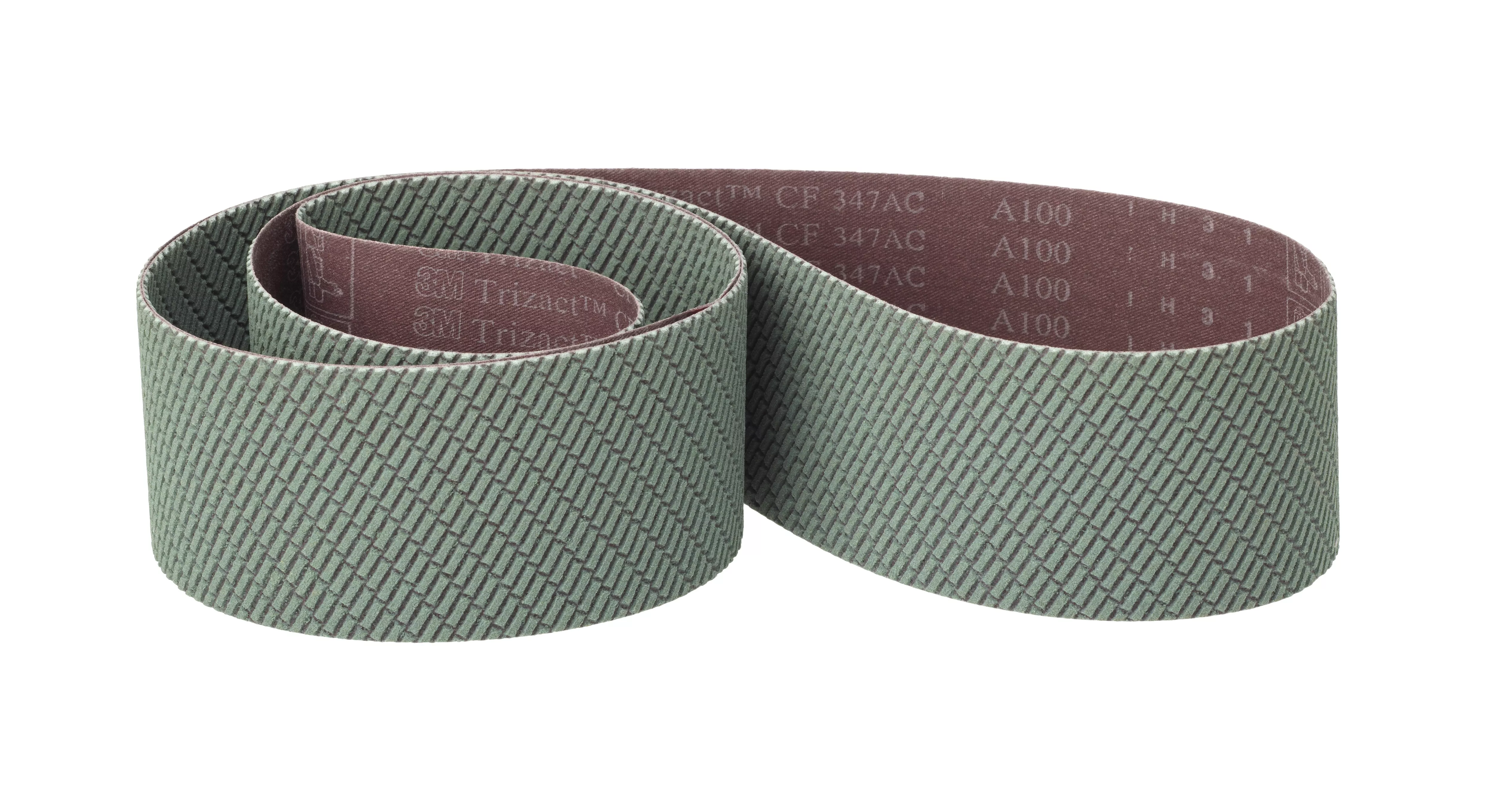

3M Trizact CF Cloth Belt 347FC features a unique formulation and bricks and channels abrasive design well suited for hard chrome grinding and finishing. The 347FC belt delivers consistent grinding performance without loading and dulling and the flexible X-weight cloth backing withstands high pressure grinding on hard metals.

- Macroreplicated abrasive structures are designed to cut faster at higher pressures abrasives with consistent results from first cut to last

- Controlled mineral breakdown delivers more consistent, predictable finishes over the life of the abrasive

- Channels efficiently remove swarf, reduce loading or capping of abrasive

- Geometric "bricks" wear evenly throughout service life due to multiple layers of mineral and grinding aid

- X-weight cloth backing withstands high-pressure grinding

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null |

Shipping Dimensions |

|

| Weight | 18.288 lb |

|---|---|

| Length | 16 in |

| Width | 16 in |

| Height | 7 in |

PRODUCT FAQ

-

bsolutely! I can help with that. Here are some commonly asked questions about the 3M™ Trizact™ CF Cloth Belt 347FC

What does "A45 X-weight" refer to in this product description?

-

The "A45 X-weight" indicates the grit size and weight of the backing material. In this case, A45 refers to a fine grit size and X-weight signifies a heavy-duty cloth backing.

How many belts come in one case of the 3M™ Trizact™ CF Cloth Belt 347FC?

-

Each case contains 20 belts of the 2-3/4 inch x 160 inch size.

What does it mean for this belt to have "No Flex"?

-

The "No Flex" feature ensures consistent contact and pressure during sanding applications, leading to more uniform results.

Can Film-lok be easily attached and detached from sanding tools?

-

Yes, the Film-lok system allows for quick and easy attachment and removal from compatible tools without sacrificing security during use.

; How does the Trizact technology benefit users compared to traditional abrasives?

-

; Trizact abrasive material offers longer product life, shorter process times, reduced heat generation during grinding tasks which could result in improved quality finishes on metals or wood.

In tandem with the consistency of the Trizact abrasive, the ease and versatility of a belt dimensioning process may mean 3M Trizact CF Cloth Belt 347FC can boost productivity, streamline process steps, and increase the number of parts produced per belt.

This belt is available in grades from A300 for quick stock removal to A30 for fine finishes and in widths up to 25 inches.

Recommended ApplicationsMicroreplication - the Science of Smooth

Traditional grinding and finishing methods are proving less effective on many newer, hard-to-grind materials, slowing down production and driving up costs. Now, 3M brings a broad range of solutions designed to meet today's tough processing challenges. The three-dimensional structures of 3M Trizact Abrasives contain multiple layers of mineral. As these structures wear, fresh, sharp mineral is constantly exposed to the workpiece, resulting in faster, more consistent cutting.

- High-pressure, final finish, and polishing on hard metals, nickel alloys, titanium, and stainless steel.

- 3M Trizact CF Cloth Belt 347FC features a unique formulation and abrasive pattern well suited for hard chrome grinding and finishing.

- Grade A160 strips and finishes. Rely on A160 for efficient stock removal and also to achieve a fine finish.

- 3M Trizact abrasive products start sharp and stay sharp, resulting in more predictable finishes and improved, consistent quality in your parts. Derived from proprietary 3M technology, Trizact abrasives are precisely-shaped three-dimensional structures, distributed uniformly over a backing. Multiple layers of mineral in Trizact abrasives extend abrasive life. Elimination of part-to-part variation boosts productivity profoundly.

3M allows more cost-effective ways to obtain predictable, consistent, and repeatable finishes faster than ever before.