| SKU | 7100291710 |

|---|---|

| Legacy SKU | 61500336104 |

| UPC | 00068060658388 |

| Product Number | 645DC |

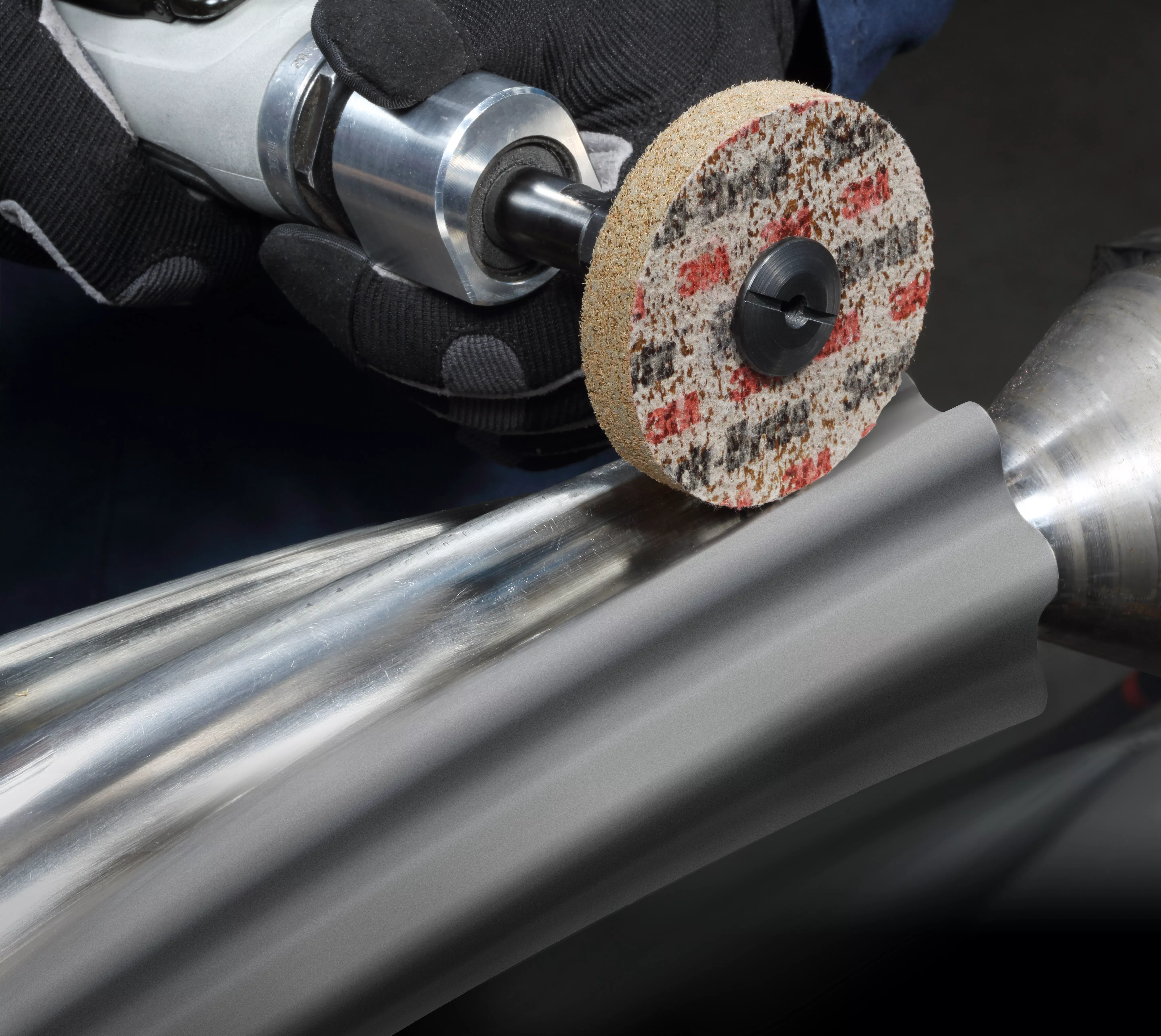

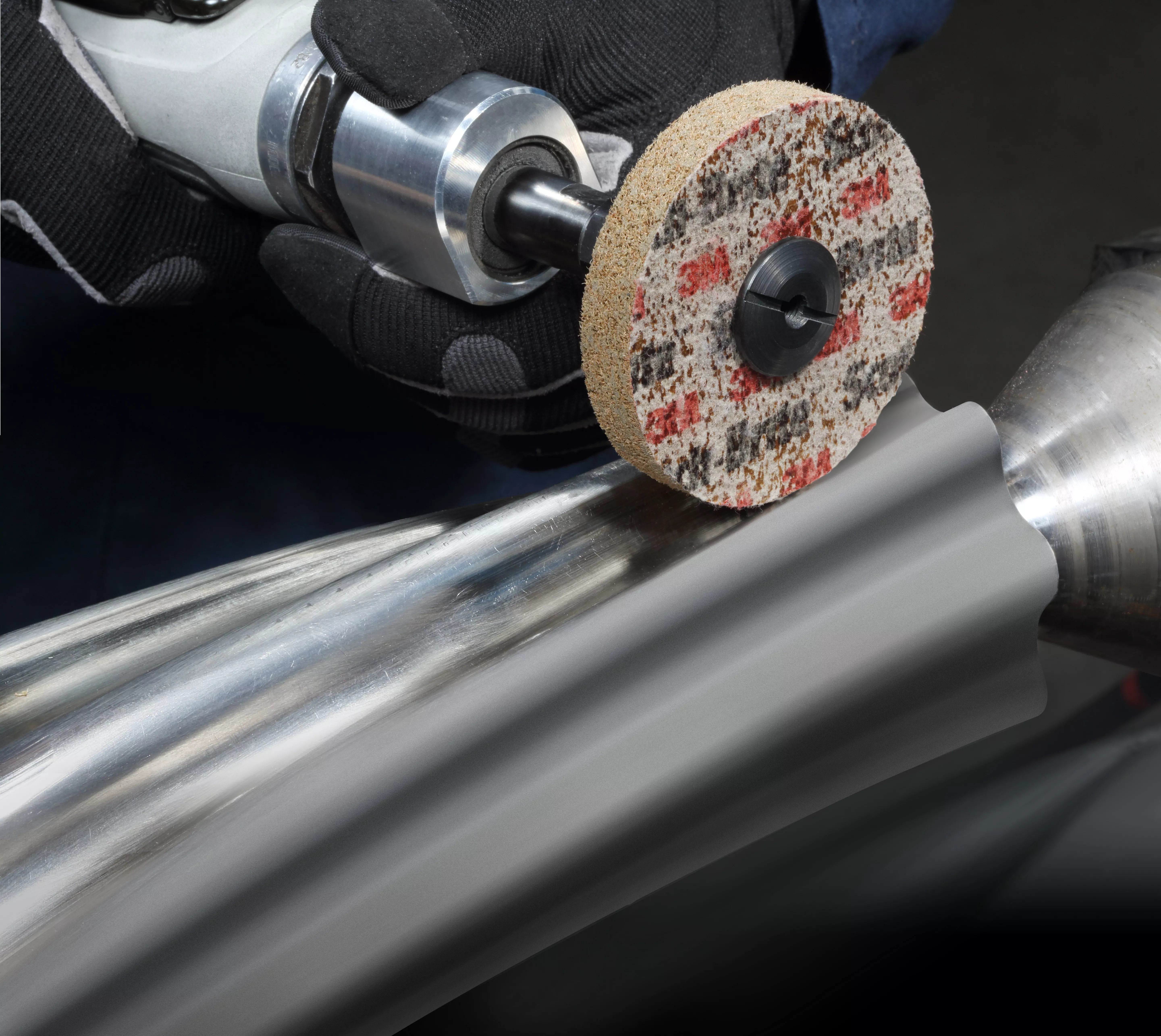

Scotch-Brite Diamond Wheel, 645DC is a unique surface conditioning wheel containing diamond mineral for removal and pre-polishing of extra-hard materials such as carbide thermal spray and ceramics.

- Removes and finishes thermal spray parts in one step with Ra in the 12-16 range

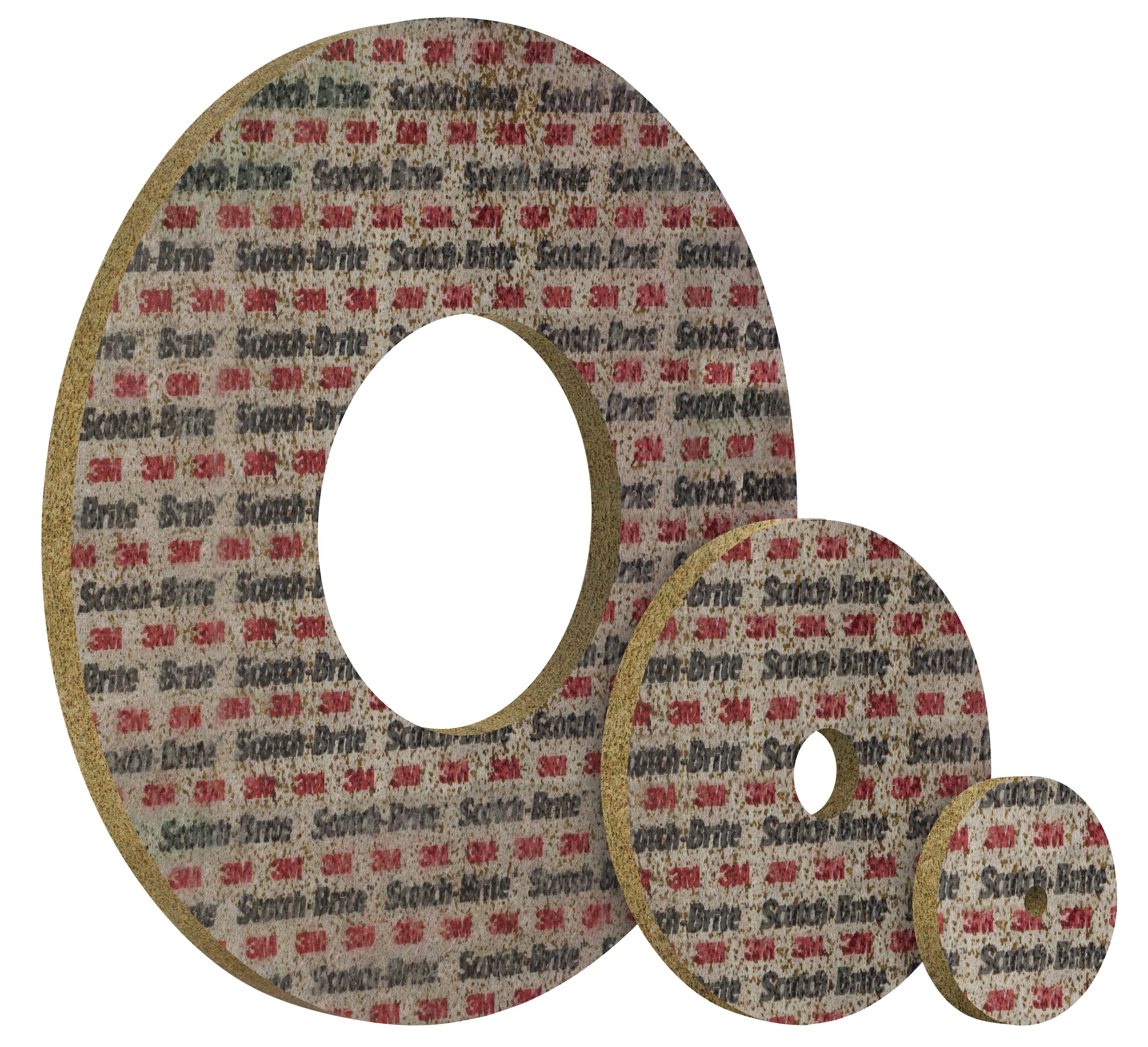

- Available in 12”, 6” and 3” diameters and in multiple thicknesses

- Provides a consistently fine, burr-free finish

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 1 in | 25.4 mm |

| Thickness | 1 in | 25.4 mm |

| Center Hole Diameter | 0.188 in | 4.763 mm |

Shipping Dimensions |

|

| Weight | 0.89309 lb |

|---|---|

| Length | 6.41732 in |

| Width | 4.68504 in |

| Height | 4.68504 in |

| Maximum Speed | 25,000 rpm |

|---|

PRODUCT FAQ

-

What is the grit size of the Scotch-Brite™ Diamond Wheel 645DC?

The Scotch-Brite™ Diamond Wheel 645DC has a grit size of 125 Mic, which offers precise and consistent finishing results.

-

How big is each individual wheel in the case?

Each Scotch-Brite™ Diamond Wheel in this case measures 1 inch by 1 inch by 3/16 inch, perfect for various applications requiring precision.

-

How many wheels are included in one case?

There are a total of 50 Scotch-Brite™ Diamond Wheels included in one case, providing great value for your needs.

-

What makes the Scotch-Brite™ Diamond Wheel stand out compared to other options on the market?

The Scotch-Brite™ Diamond Wheel boasts superior performance and durability, making it an excellent choice for achieving high-quality finishes with ease.

The Scotch-Brite Diamond Wheel, 645DC, is specifically designed to provide significant process improvements in the grinding and finishing of thermal spray and other hard-to-grind substrates. What sets it apart is its diamond mineral abrasive, which ensures a consistently fine and burr-free finish throughout the entire lifespan of the wheel.

Discover the Scotch-Brite AdvantageScotch-Brite abrasives stand out due to their unique nonwoven technology. The abrasive mineral is embedded on synthetic fibers using resin, creating an open web construction. This construction allows excess material to escape, preventing the mineral from becoming worn down by debris. As a result, the mineral remains sharp for a longer period, enhancing cut performance and increasing the overall service life of the abrasive. The spring-like nature of the fibers also makes them highly effective on contours and responsive to surface subtleties. This design ensures the removal of unwanted burrs, soils, and contaminants without damaging the base material, resulting in a consistent and uniform finish for each part.

Typical Applications- Composites

- Carbon fiber

- Thermal spray

- Hard-to-grind surfaces