| SKU | 7000136525 |

|---|---|

| Legacy SKU | 61500152204 |

| UPC | 00048011276755 |

| Product Number | SC-DH |

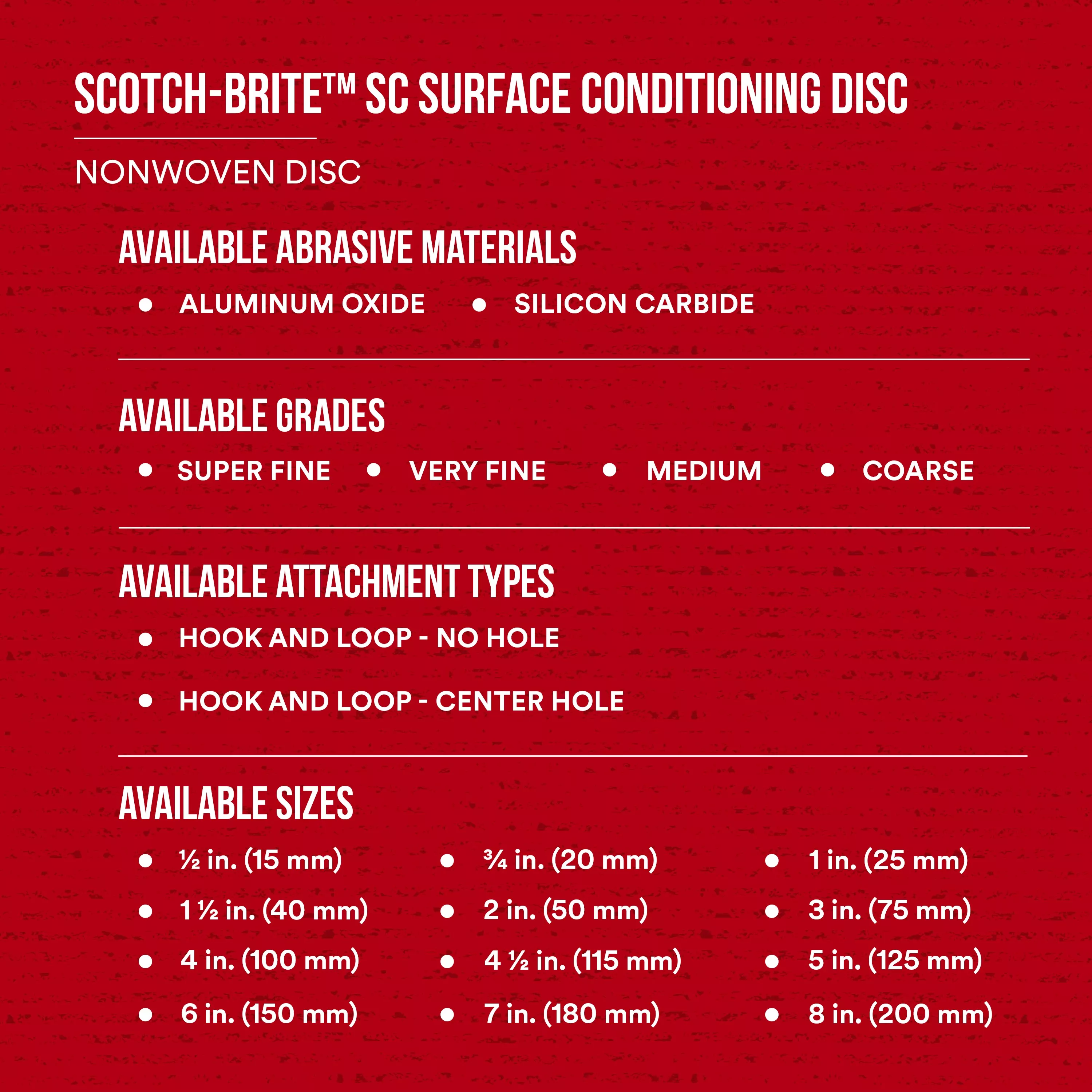

Scotch-Brite Surface Conditioning Disc comes in a wide variety of grades and sizes and is an ideal first-step for cleaning, blending, deburring, and finishing. Durable, nonwoven fiber construction conforms well on irregular or contoured surfaces without undercutting or damaging the base material.

- GREAT FOR LOW-MEDIUM PRESSURE: Built for consistency in blending, cleaning, deburring, finishing, grinding, polishing, radiusing, refining and surface preparation

- CONFORMABLE NONWOVEN WEB: Springy nonwoven fibers resist loading and conform to irregular or contoured surfaces

- WORKS ON A RANGE OF METALS: Great for use on aluminum, mild steel, nickel alloy, stainless steel and titanium

- QUICK AND EASY ATTACHMENT: Hook and loop backing makes for easy disc attachment, removal and re-attachment

- CHOOSE YOUR MINERAL: Super Fine grade is powered by super-sharp silicon carbide that excels in low-pressure and fine finishing applications, while all other grades feature harder and more durable aluminum oxide

- AVAILABLE IN A RANGE OF GRADES: Choose from Super Fine (SFN), Very Fine (VFN), Medium (MED) and Coarse (CRS) to fit your application needs

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 5 in | 127 mm |

| Center Hole Diameter | 0.0 NP |

Shipping Dimensions |

|

| Weight | 0.696 lb |

|---|---|

| Length | 5.98425 in |

| Width | 5.98425 in |

| Height | 3.97638 in |

| Color | Maroon |

|---|---|

| Thread Size | Non Pertinent |

| Maximum Speed | 10,000 rpm |

PRODUCT FAQ

-

What is the difference between a surface conditioning disc and an abrasive disc?

While both types of discs work to remove material from surfaces, surface conditioning discs also simultaneously create a smoother finish and can prepare surfaces for painting or other coatings.

-

How long does the Scotch-Brite Surface Conditioning Disc last?

The lifespan of the disc depends on its specific application and use. However, it has excellent durability due to its fiber-reinforced construction that resists tearing while maintaining flexibility.

-

Do I need any special tools or equipment to use this product?

This particular 3M Scotch-Brite™ Surface Conditioning Disc can be used with most standard hand-held rotary sanders in compliance with ANSI B7.1 safety requirements.

-

Can I use this disc on any type of metal surface?

Absolutely! The SC-DH model is designed for medium-duty grinding applications on all metals, including stainless steel, carbon steel, aluminum, copper alloys, brass, bronze and more!

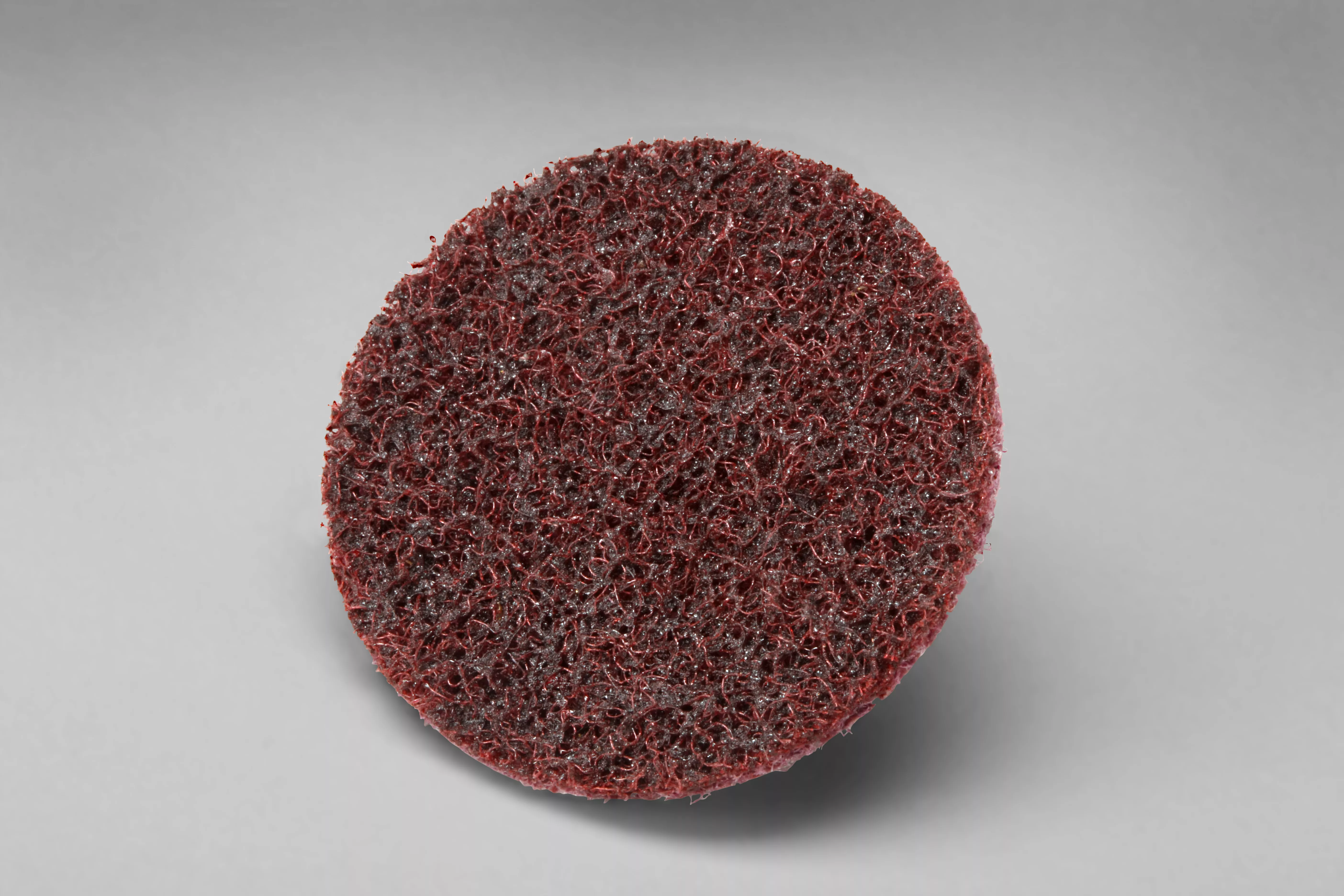

Scotch-Brite Surface Conditioning Discs are the perfect solution for cleaning, blending, deburring, and finishing all types of metals. These 5” surface conditioning discs are made with durable, conformable nonwoven fibers that work exceptionally well on irregular or contoured metal surfaces without causing any damage to the base material.

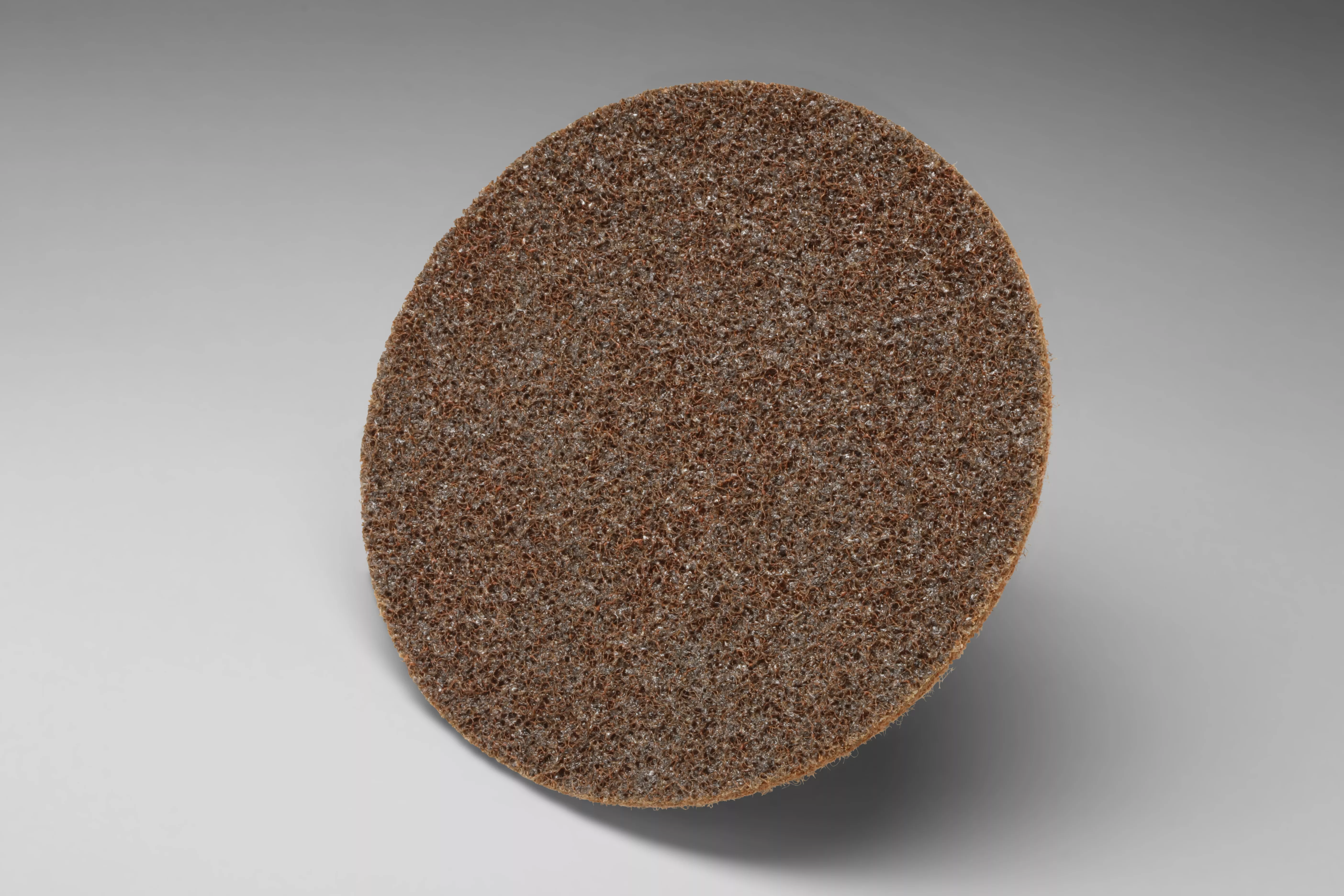

The medium grit aluminum oxide mineral is evenly distributed within the nonwoven fiber to provide a consistent cut during rust removal, weld cleaning, deburring, and other metalworking surface preparation. The combination of abrasive mineral with the fibers results in a deburring disc that delivers consistent results throughout the life of the product.

The 3M hook-and-loop attachment on the backside of the surface conditioning disc makes it easy to attach and change-out discs in multi-step metal surface preparation processes. Simply attach the surface conditioning disc to a hook-and-loop backup pad on either a right-angle grinder or random orbital sander and run the tool at a maximum of 13,000 rpm.

- Perfect for cleaning, blending, deburring, and finishing all types of metals

- Durable, conformable nonwoven fibers work great on irregular or contoured metal surfaces

- Medium grit aluminum oxide mineral provides a consistent cut during rust removal, weld cleaning, deburring, and other metalworking surface preparation

- 3M hook-and-loop attachment makes it easy to attach and change-out discs in multi-step metal surface preparation processes

- Simply attach the surface conditioning disc to a hook-and-loop backup pad on either a right-angle grinder or random orbital sander and run the tool at a maximum of 13,000 rpm