| SKU | 7010307723 |

|---|---|

| Legacy SKU | 60410017556 |

| UPC | 00051125949651 |

| Product Number | 987C |

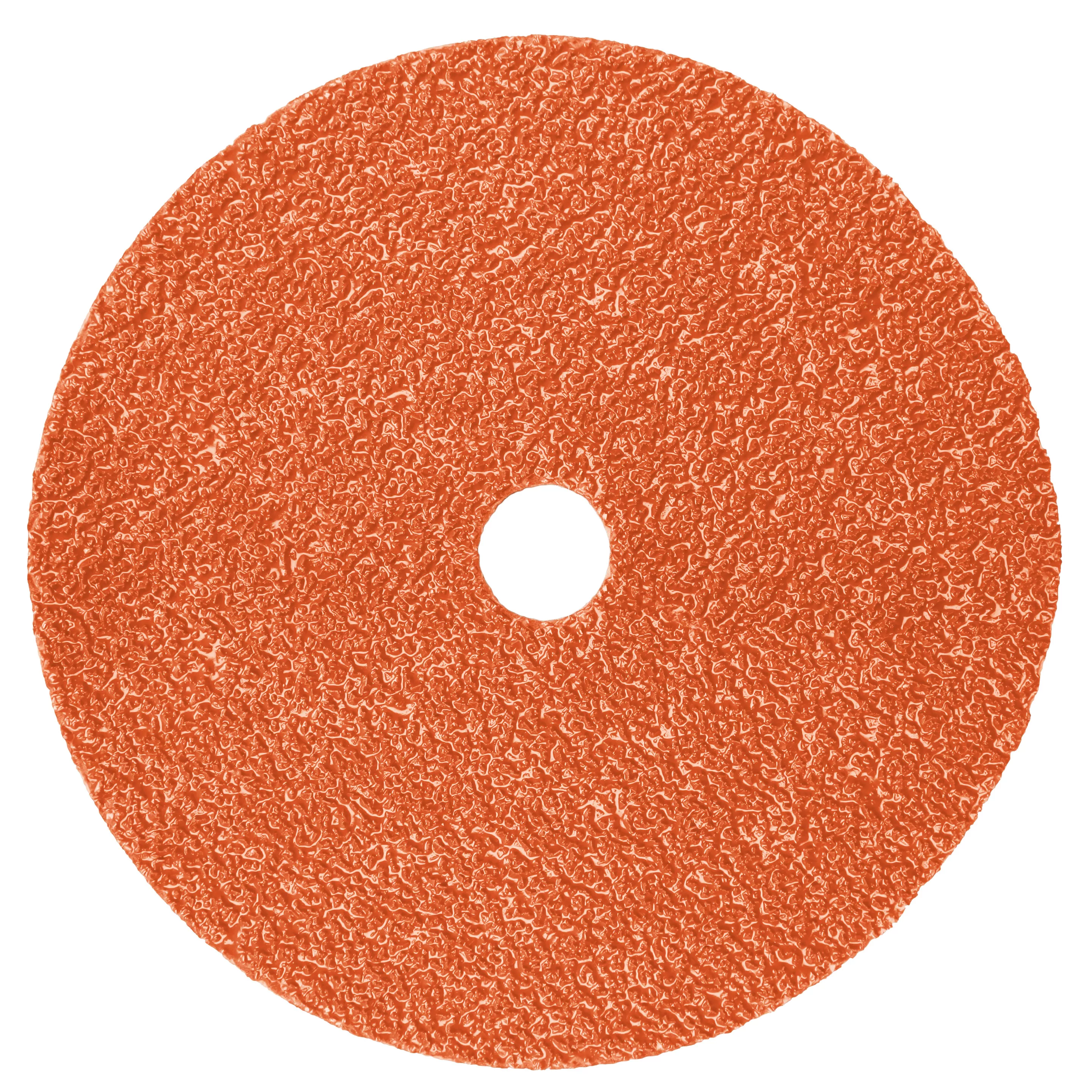

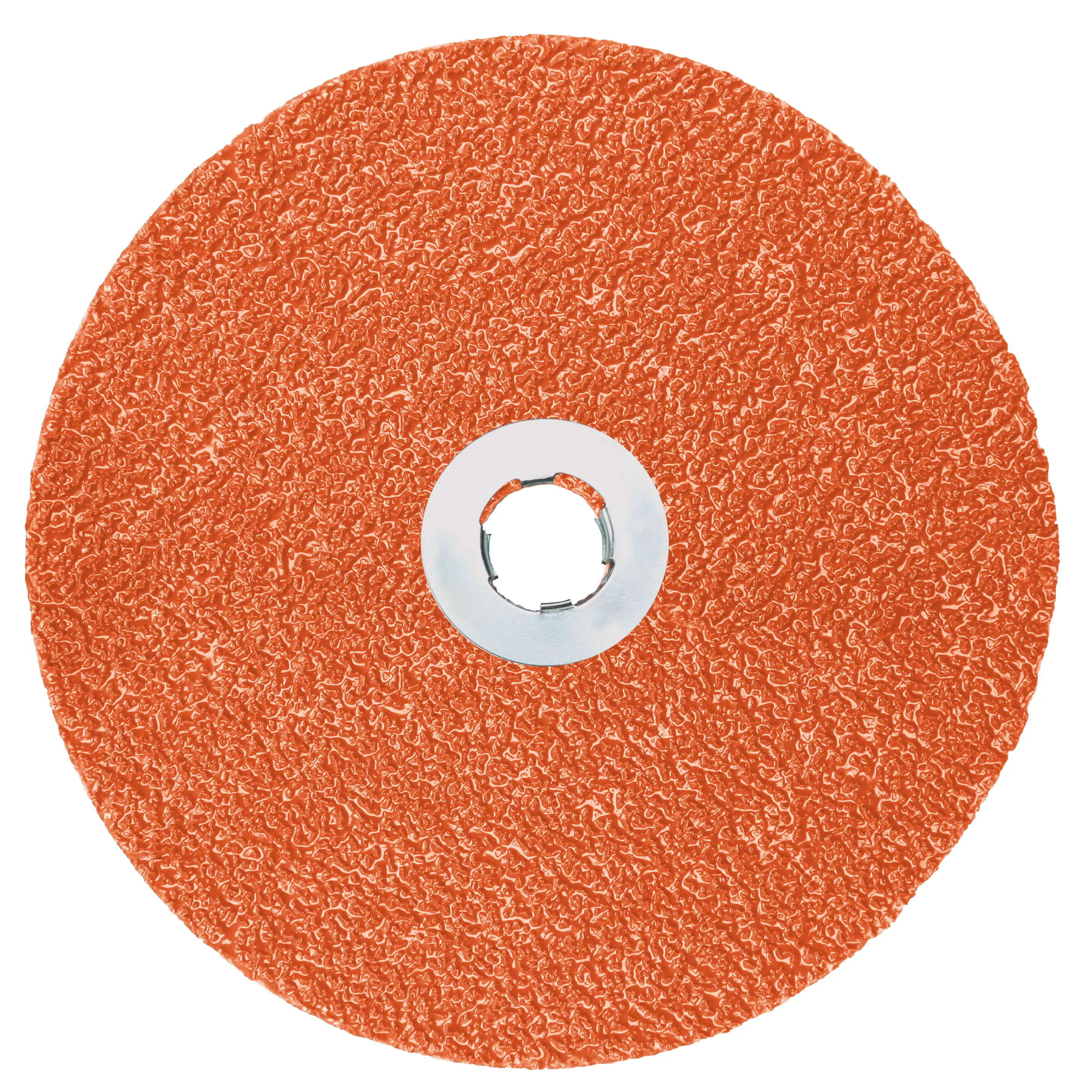

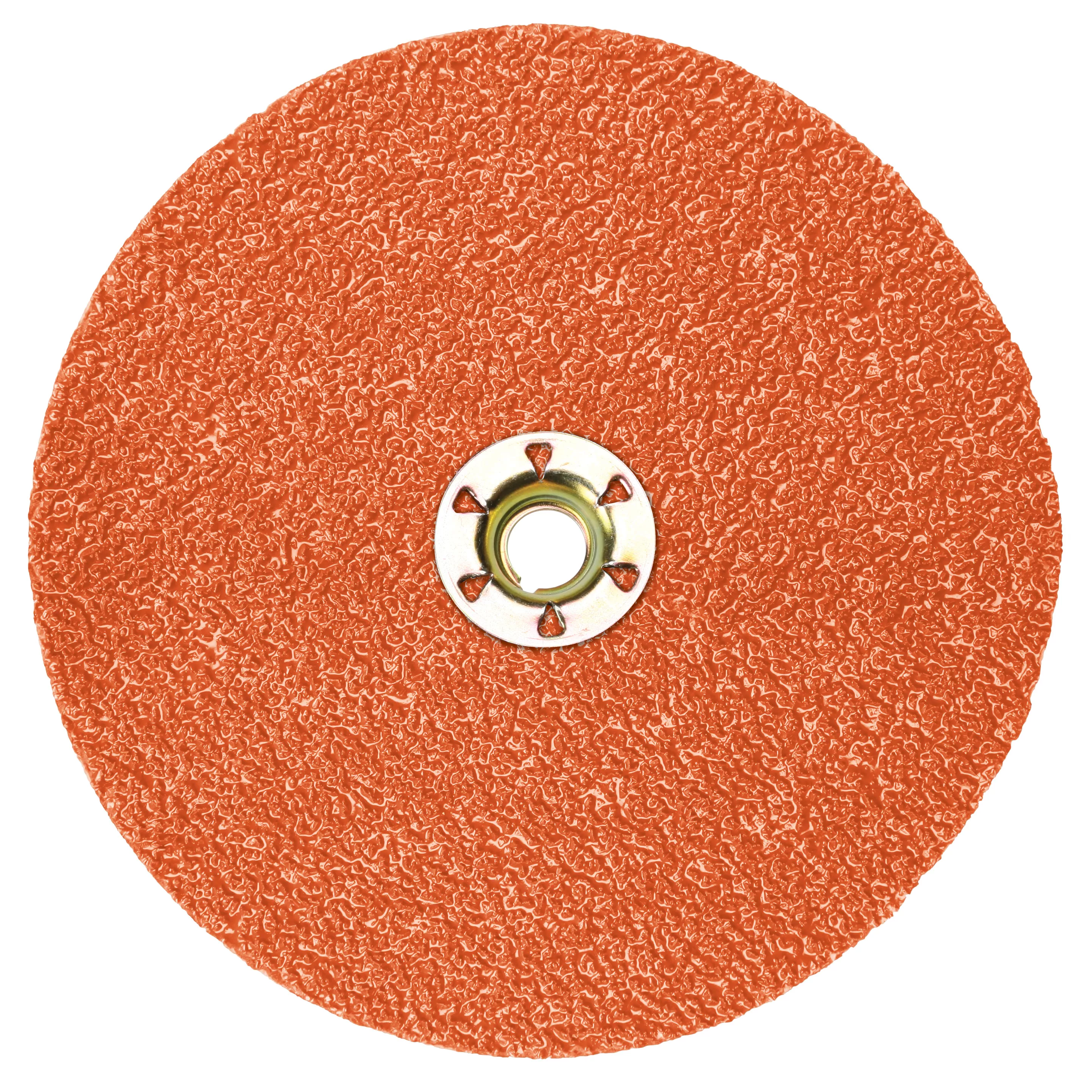

The 3M Cubitron II Roloc Fibre Disc 987C is designed for heavy duty metalworking applications such as weld grinding, beveling and flame-cut edge clean-up. This product uses 3M Precision-Shaped Grain on a fiber backing for fast grinding and blending.

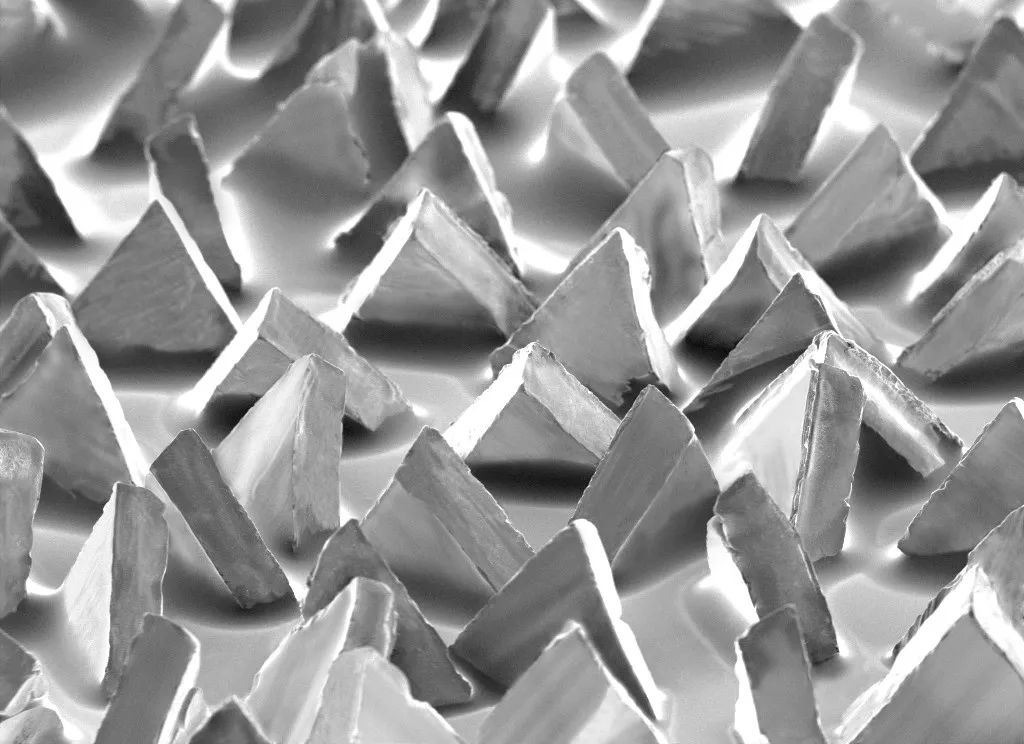

- 3M Precision Shaped Grain (PSG) maintains super-sharp points that cut exceptionally fast with less pressure

- PSG runs cooler, reducing metal discoloration/oxidation and the chance of heat related stress cracks

- Disc life is significantly longer, completing more parts per disc and requiring fewer disc changes

- Grinding aid reduces grinding temperatures for processes involving heat-sensitive alloys such as stainless steel, nickel alloys and titanium

- 3M™ Roloc™ attachment system provides for easy disc changes between grades or applications

- Stiff fiber backing and a strong resin bond provide durability and tear-resistance for heavyweight applications such as high-pressure weld grinding

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 2 in | 50.8 mm |

| Center Hole Diameter | 0.0 NP |

Shipping Dimensions |

|

| Weight | 4.108 lb |

|---|---|

| Length | 9.70984 in |

| Width | 9.12992 in |

| Height | 5.07992 in |

| Color | Orange |

|---|---|

| Thread Size | Non Pertinent |

| Maximum Speed | 25,000 rpm |

PRODUCT FAQ

-

What is the size of the 3M™ Cubitron™ II Roloc™ Fibre Disc 987C?

The diameter of this disc is 2 inches.

-

How many discs are included in one case of 3M™ Cubitron™ II Roloc™ Fibre Disc 987C, 80+, TSM?

There are a total of 200 discs per case, with each inner containing 50 discs.

-

Can you tell me more about the technology used in the making of these discs?

Certainly! The Cubitron II abrasive technology utilized in these discs helps them cut faster and last longer than traditional grinding and sanding products. Additionally, their precision-shaped grain allows for a consistent finish with minimal pressure required from the user.

3M™ Fibre 987C products incorporate a grinding aid to keep the workpiece cooler, protecting heat-sensitive alloys from heat damage and reducing re-work. These features offer increased productivity for heavy-duty grinding on all metals, including stainless steel.

Recommended Applications- Heavy duty metalworking applications

- Flame-cut edge cleanup

- Grinding

- High pressure grinding

- Right angle grinding

- Edge chamfering

- Weld removal and finishing

- Edge beveling

- Gate removal

To create PSG, engineers start with 3M™ Ceramic Abrasive Grain and use proprietary technology to form the grains into triangular structures and electrostatically orient them on the backing to form sharp peaks that maximize cutting potential. These peaks slice cleanly through metal, rather than gouging or plowing as traditional abrasive grains do; and continuously self-sharpen as the points break off. This generates a super-fast cut and lessens heat build-up due to friction, reducing heat-related stress cracks and discoloration. PSG also wears evenly, and because the abrasive stays cooler and sharper, Cubitron II products last significantly longer than their conventional ceramic counterparts, ensuring extended high performance in production applications. Cubitron™ II products achieve a fast cut rate and a long product life.