| SKU | 7010329293 |

|---|---|

| Legacy SKU | 61500193299 |

| UPC | 00048011338194 |

| Product Number | SL-DR |

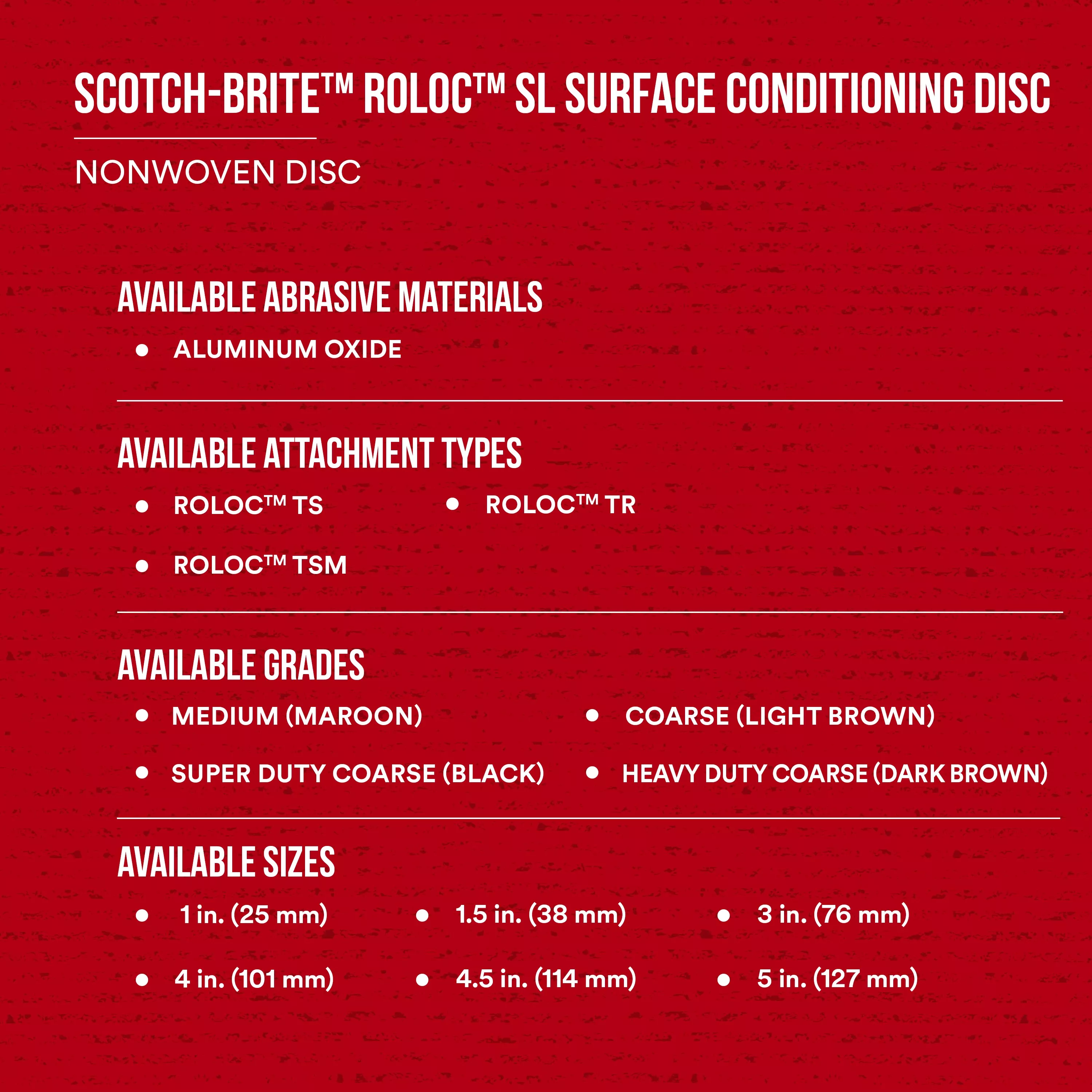

The Scotch-Brite Roloc SL Surface Conditioning Disc is a durable product that combines blending and finishing capability with aggressive cut. Its unique web construction and formulation allows the disc to resist loading while giving you an aggressive cut and long product life on both edges and flat surfaces.

- BUILT FOR VERSATILITY: Makes quick work of blending, deburring, finishing, grinding, radiusing, refining and surface preparation

- LONG-LASTING PERFORMANCE: Specially engineered for durability and long abrasive life

- WORKS ON A RANGE OF METALS: Great for use on aluminum, mild steel, nickel alloy, stainless steel and titanium

- QUICK AND EASY ATTACHMENT: Convenient 3M™ Roloc™ attachment system allows for fast disc changes

- TOUGH ENOUGH FOR HEAVY-DUTY USE: Combination of aluminum oxide grain and moderate conformability makes for a tough, durable surface conditioning disc

- AVAILABLE IN A RANGE OF GRADES: Choose from Medium (MED), Coarse (CRS), Heavy-duty (CRS HD) and Super Duty (CRS SD) to fit your application needs

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 4 in | 101.6 mm |

| Center Hole Diameter | 0.0 NP |

Shipping Dimensions |

|

| Weight | 6.95338 lb |

|---|---|

| Length | 14.6248 in |

| Width | 14.6248 in |

| Height | 8.06299 in |

| Color | Black |

|---|---|

| Maximum Speed | 12,000 rpm |

PRODUCT FAQ

-

What is the Scotch-Brite™ Roloc™ SL Surface Conditioning Disc used for?

The 3M Scotch-Brite™ Roloc™ SL Surface Conditioning Disc can be used for preparing metal surfaces before painting, blending away scratches and other surface imperfections, deburring or removing rust, oxides and coatings.

-

What does Super Duty Coarse mean in the product description?

Super Duty Coarse describes the abrasive grade of this disc. It indicates that it has a more aggressive cutting power compared to discs with lower abrasive grades, making it ideal for heavy stock removal operations on tough surfaces.

-

How is the Scotch-Brite Roloc attachment method different from regular sanding disc adhesives?

Unlike standard adhesive systems that rely on glue to attach abrasives to their backings, our unique 3M Roloc quick change system utilizes a secure twist-on/twist-off fastening mechanism that locks each disc securely in place without screws or bolts - saving you time while changing out discs mid-operation.

-

What size are these discs?

The 3M Scotch-Brite™ Roloc™ SL Surface Conditioning Discs come in a compact 4 inch diameter size. Our small yet sturdy design allows for greater control of your grinding and polishing operations giving you precise results every time.

-

Can I purchase these discs individually instead of by case?

The Scotcch-Brite ™Rolloc sl-surface conditioning super duty coarse tr comes with 100 pieces per case but we do offer smaller quantities as well.The option to buy individual packs vary between sellers but you may always check with them if they have this option available.

Scotch-Brite™ Roloc™ SL Surface Conditioning Discs are a versatile solution for weld clean up, grindline refinement, metal blending, and light deburring. With four grades available, including Medium, Coarse, Heavy Duty, and Super Duty, these open-web, non-woven discs run cool, resist loading, and maintain cut-rate consistency throughout their life. This allows for less pressure, reducing fatigue and maximizing disc life.

Aluminum Oxide Abrasive MineralThe Scotch-Brite™ Roloc™ SL Surface Conditioning Disc uses aluminum oxide abrasive mineral, which is a popular choice among industrial professionals due to its cut-rate and long life. This mineral is tough and durable, self-fracturing to expose fresh cutting edges in use. It is widely used in grinding applications, as well as sanding and finishing use, due to its high cut-rate, hardness, strength, and low heat retention. Aluminum oxide is suitable for use on a wide variety of substrates in both woodworking and metalworking, including ferrous alloys.

3M™ Roloc™ TR Quick Change Discs3M™ Roloc™ TR quick change discs are smaller discs that quickly attach onto a Roloc™ disc pad (sold separately) for convenient and quick disc changes as needed. The Roloc TR and TSM systems provide a secure attachment, even for heavy-duty applications. The variety of other 3M Roloc discs allows for swapping from one application to the next in seconds. Each disc is color-coded to identify its grade, making it easy to grab the grade required for different applications.

Scotch-Brite™ Surface Conditioning ProductsScotch-Brite™ surface conditioning products were developed with abrasives incorporated into non-woven nylon or synthetic fibers. This combination creates an abrasive system that delivers consistent results for the life of the product. The open-web material runs cool, reducing the risk of part discoloration and warping. The fibers are load-resistant and keep the abrasive minerals cutting at high performance by limiting clogging of the fibers, which also extends the life of the disc.