| SKU | 7000044740 |

|---|---|

| Legacy SKU | 60020007211 |

| UPC | 00051144841653 |

| Product Number | 366L |

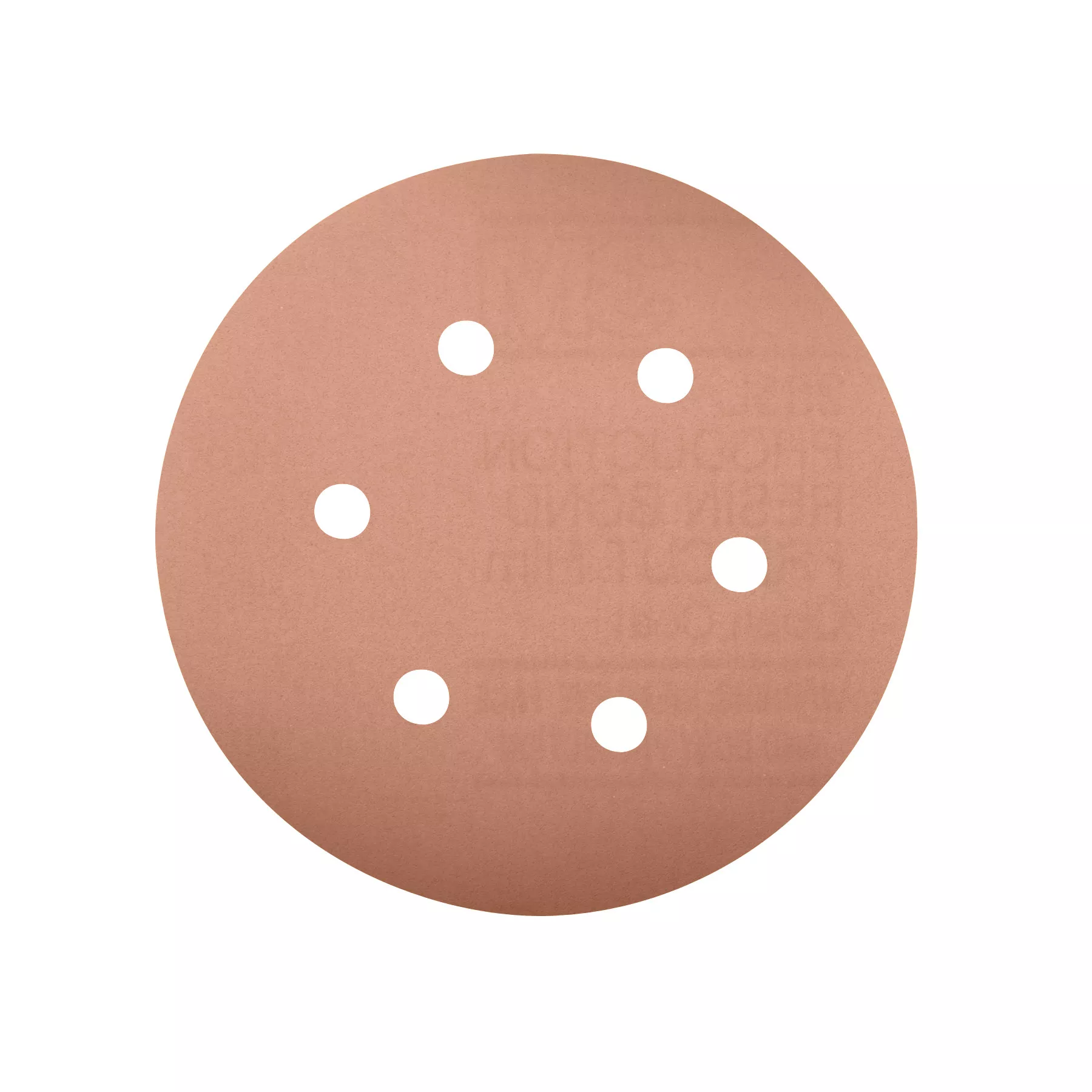

3M Hookit Microfinishing Film Disc 366L is rated Best in the 3M Microfinishing line of film backed discs. It features premium, micron-graded aluminum oxide abrasive bonded to a durable polyester film backing to produce a fast cut-rate and uniform finish on wood, solid surface composites, plastic, fiberglass, paint prep, coating and corrosion removal, primer, e-coat, or metal.

- Aluminum oxide abrasive offers a fast cut, long life, and professional performance on many surfaces

- Durable polyester film backing enables close-tolerances and consistent finish

- Hookit™ hook and loop backing allows quick attachment and removal for multi-step finishing processes

- Load-resistant coating prevents dust and debris from clogging the disc

- Available in both open coat and dust control

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

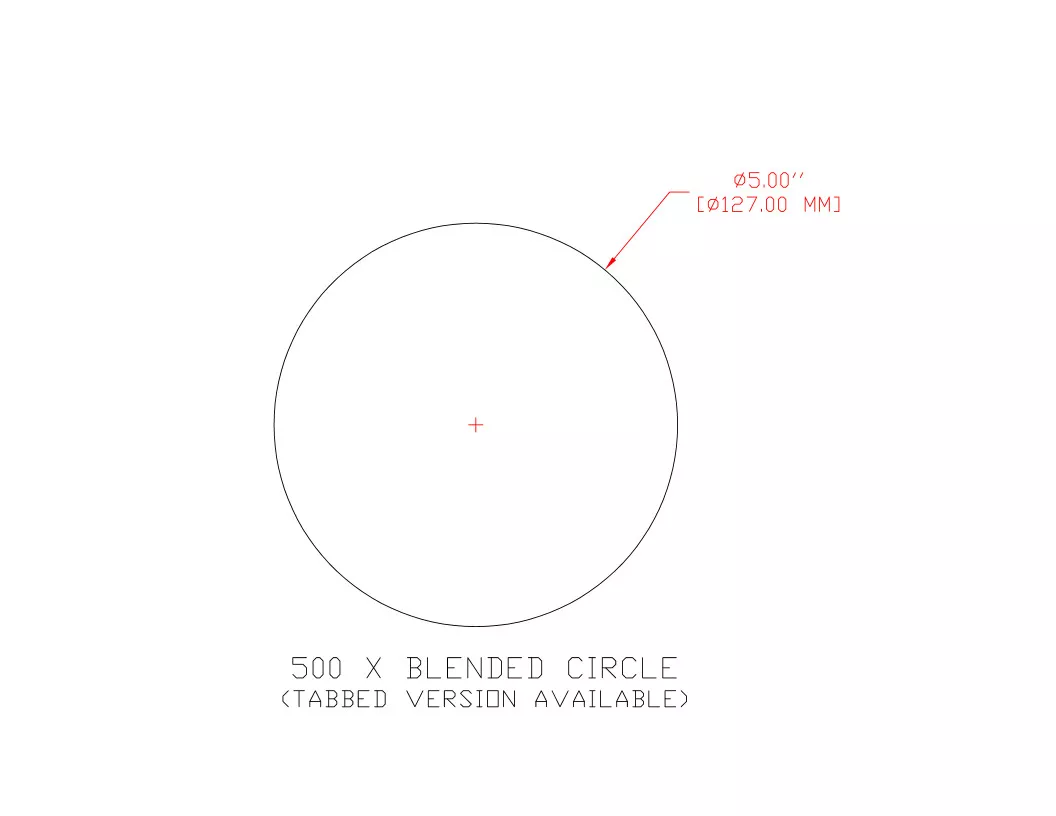

| Diameter | 5 in | 127 mm |

| Center Hole Diameter | 0.0 NP |

Shipping Dimensions |

|

| Weight | 7.09448 lb |

|---|---|

| Length | 12.00787 in |

| Width | 12.00787 in |

| Height | 4.80315 in |

| Color | Blue |

|---|---|

| Maximum Speed | 12,000 rpm |

PRODUCT FAQ

-

What is the purpose of 3M™ Hookit™ Microfinishing Film Disc 366L, 40 Mic 3MIL, Type D?

The main purpose of this product is to provide an improved cut rate and finish compared to traditional abrasive products. It utilizes a micron-graded aluminum oxide mineral with polyester film backing that offers a uniform finish while reducing dust.

-

What sizes are available for the 3M™ Hookit™ Microfinishing Film Disc 366L, 40 Mic 3MIL, Type D?

This particular item comes in variations of diameter size (including five inches), although there may be additional dimensions manufactured by the company upon request.

-

How long will one case last me?

Each case contains up to five hundred units; depending on your usage requirements or business needs it could cover you anywhere from several weeks to several months. As far as longevity per disc goes - due to factors such as grit and intensity used during abrasion - we cannot typically guarantee exact numbers per customer.

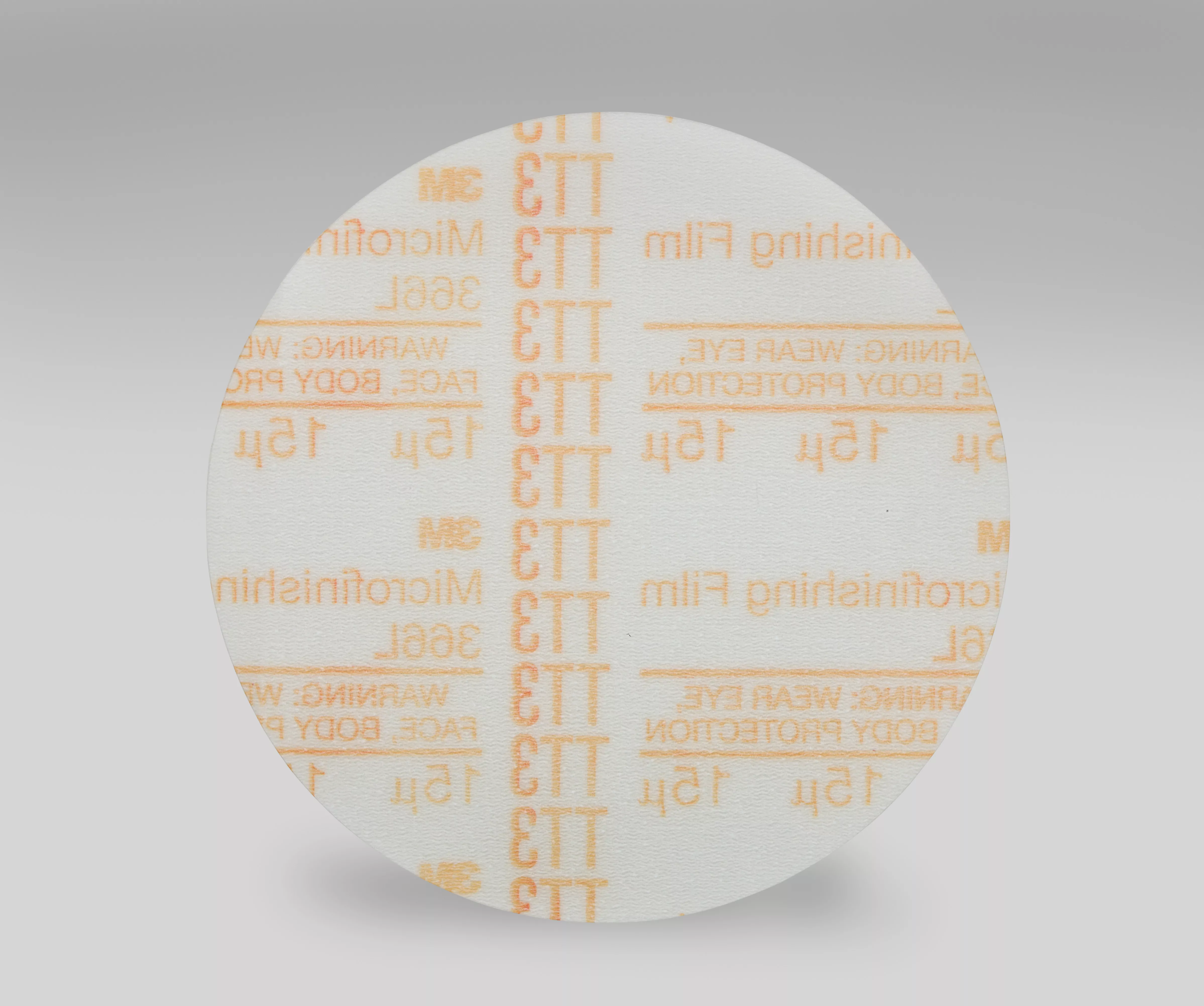

The 3M™ Hookit™ Microfinishing Film Disc 366L is a high-quality abrasive product designed for use with orbital and random orbital sanders. It features precision, micron-graded aluminum oxide, which is a popular choice among industrial professionals because of its fast cut-rate and long life. This mineral makes a tough, durable abrasive that self-fractures to expose fresh cutting edges, whereas traditional natural abrasives dull more quickly. Due to its fast cut-rate, hardness, and strength, it is widely used in grinding applications in addition to sanding and finishing applications. Aluminum oxide is suitable for a wide variety of materials in both woodworking and metalworking, including ferrous alloys.

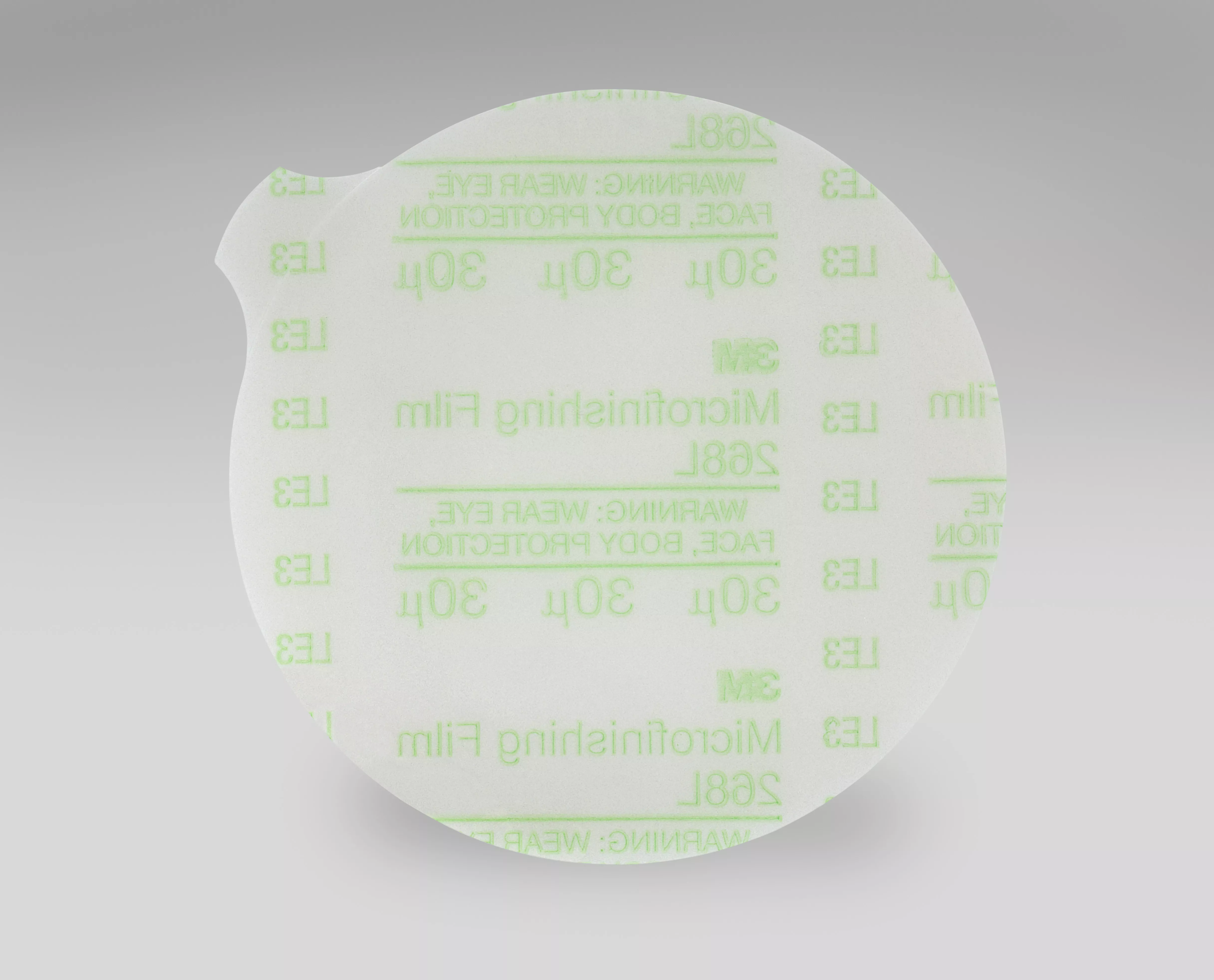

These discs feature a load resistant coating to increase efficiency and product life by minimizing loading. The abrasive is resin-bonded and supports disc flexibility without sacrificing durability and reliable performance under high heat and pressure. To complement the effective abrasive action, the polyester film backing flexes to help achieve a consistent finish over contours and offers greater tear-resistance than comparable paper products, making it ideal for high-production environments. And the 3M™ Hookit™ attachment and removal system holds the disc securely during use and provides easy disc change out.

Whether the job requires a random orbital or rotary sander, buffer, grinder, drill, finishing sander or other power tool, hook-and-loop products allow the operator to focus more on the task and less on tooling. Abrasive products with hook-and-loop backing, including 3M™ Hookit™ products, are manufactured with loop material that attaches to a backup pad, sold separately, where tiny hooks firmly engage the loops. Attachment is quick, easy, and secure during use. Sanding, finishing, and surface conditioning products with the hook-and-loop attachment and removal system provide an efficient way to work through multi-step finishing processes and can be used again and again for the life of the abrasive.

3M Sanding Discs3M sanding discs come in a variety of forms to fit various power tools and disc pads. Hook and Loop sanding discs are designed to be used with a random orbital sander, a handheld sanding machine that rotates the disc in a random pattern to prevent swirl marks from forming on the surface of the workpiece. The sander is fitted with a backup pad (sold separately) to which the sanding disc is attached. Hook-and-loop discs are quick and easy to change when switching from one grade to another, and can be reused again and again until worn out; whereas adhesive-backed discs are typically discarded after one use because the adhesive backing will not re-adhere a second time.

- Load resistant coating to increase efficiency and product life

- Resin-bonded abrasive supports disc flexibility without sacrificing durability

- Polyester film backing flexes to help achieve a consistent finish over contours

- Greater tear-resistance than comparable paper products

- 3M™ Hookit™ attachment and removal system holds the disc securely during use and provides easy disc change out

- Designed for use with orbital and random orbital sanders

- Comes in a range of grades for complete multi-step sanding and finishing