| SKU | 7000046116 |

|---|---|

| Legacy SKU | 61500146172 |

| UPC | 00048011245270 |

| Product Number | X3-WL |

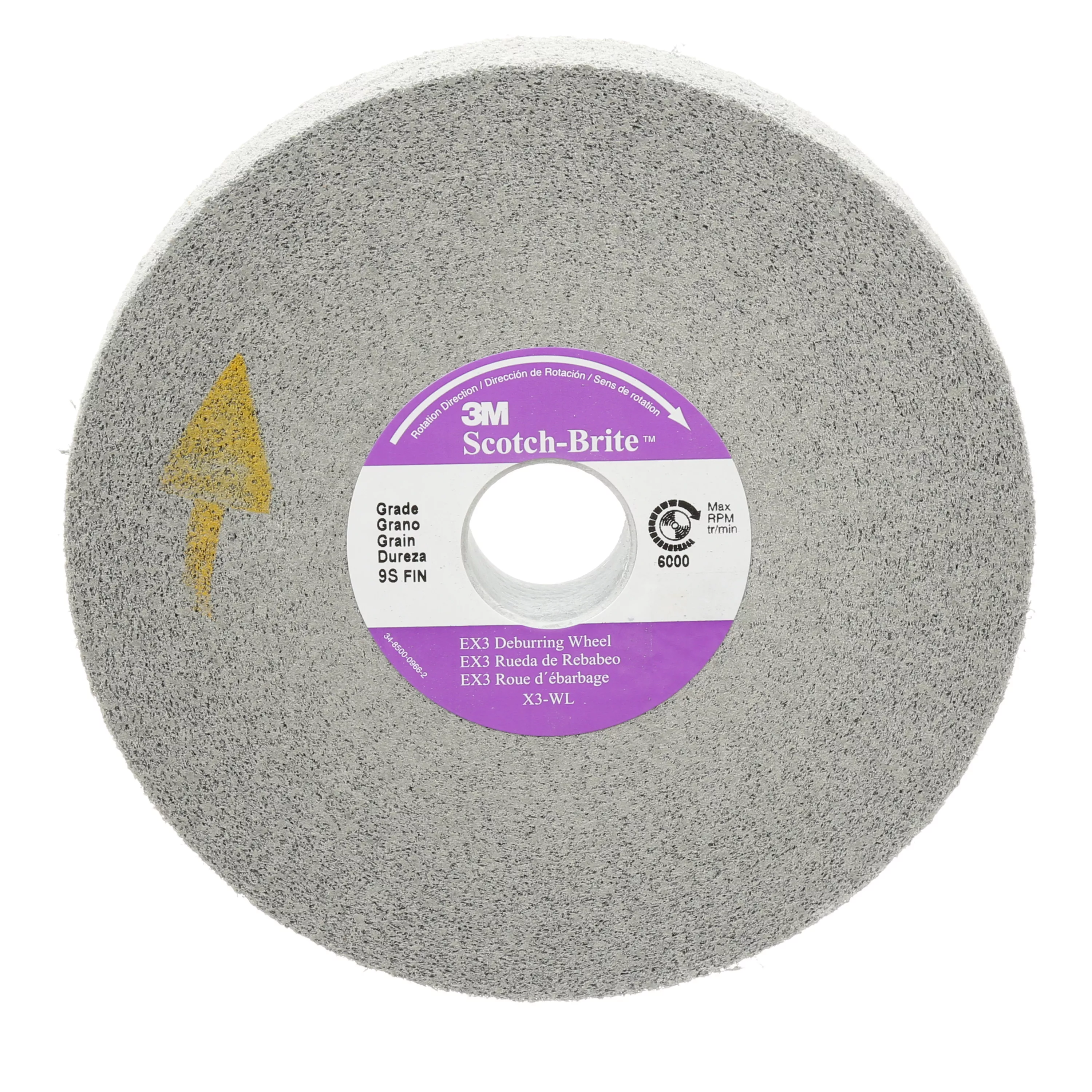

Scotch-Brite EX3 Deburring Wheel is a convolute-constructed, hard, durable deburring wheel suited for applications where edge retention is a must. The wheel performs best when consistently presented with a sharp edge or metal burrs. A unique resin system resists smearing and heat buildup.

- Highest edge retention and durability in the Scotch-Brite™ Deburring Wheel line provides aggressive edge deburring

- Specially engineered to condition sharp edges and metal burrs

- Convolute construction provides a balanced, smooth running wheel throughout product life

- Nonwoven web runs cool and lessens impact on heat-sensitive materials

- Unique resin system produces less smearing, reducing clean and prep time

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 8 in | 203.2 mm |

| Center Hole Diameter | 3 in | 76.2 mm |

Shipping Dimensions |

|

| Weight | 4.7999 lb |

|---|---|

| Length | 8.70079 in |

| Width | 8.70079 in |

| Height | 4.2126 in |

| Color | Gray |

|---|---|

| Thread Size | Non Pertinent |

| Maximum Speed | 4,500 rpm |

PRODUCT FAQ

-

What is the Scotch-Brite™ EX3 Deburring Wheel used for?

The Scotch-Brite™ EX3 Deburring Wheel is used for deburring, finishing, and polishing all types of metals.

-

How fine is the X3-WL 9S Fine wheel?

The X3-WL 9S Fine wheel has a fine grade abrasive rating that ranges from 240 to 320 grit.

-

How many wheels come in a case?

Three wheels come in each case of the Scotch-Brite™ EX3 Deburring Wheel.

Scotch-Brite™ EX3 Deburring Wheel is an effective tool for deburring, blending, finishing, and polishing edges on various materials such as glass, hard and soft composites, and metals including builder's hardware, medical instruments, metal fabrication, metal implants, plumbing fixtures, and turbine engines. However, it is not recommended for applications where conformability and finishing of flat surfaces are required due to its hard density.

The EX3 Deburring Wheel is available with either silicon carbide or aluminum oxide abrasive mineral. Silicon carbide is a synthetic mineral that is very sharp and commonly used for low-pressure applications such as paint prep and finishing. On the other hand, aluminum oxide is a hard, blocky mineral that provides high cut-rate and long life. Although silicon carbide breaks down faster than aluminum oxide, it produces a finer finish.

Scotch-Brite™ industrial abrasives are unique surface conditioning products that incorporate abrasives into non-woven nylon or synthetic fibers. This combination creates an abrasive system that delivers consistent results for the life of the product. The open-web material runs cool and is load resistant, which keeps the abrasive minerals cutting at high performance by limiting clogging of the fibers.

- Effective for deburring, blending, finishing, and polishing edges on various materials

- Available with silicon carbide or aluminum oxide abrasive mineral

- Silicon carbide produces a finer finish while aluminum oxide provides high cut-rate and long life

- Scotch-Brite™ industrial abrasives deliver consistent results for the life of the product

- The open-web material runs cool and is load resistant, which keeps the abrasive minerals cutting at high performance by limiting clogging of the fibers