| SKU | 7010366865 |

|---|---|

| Legacy SKU | 61500298148 |

| UPC | 00048011647258 |

| Product Number | X3-WL |

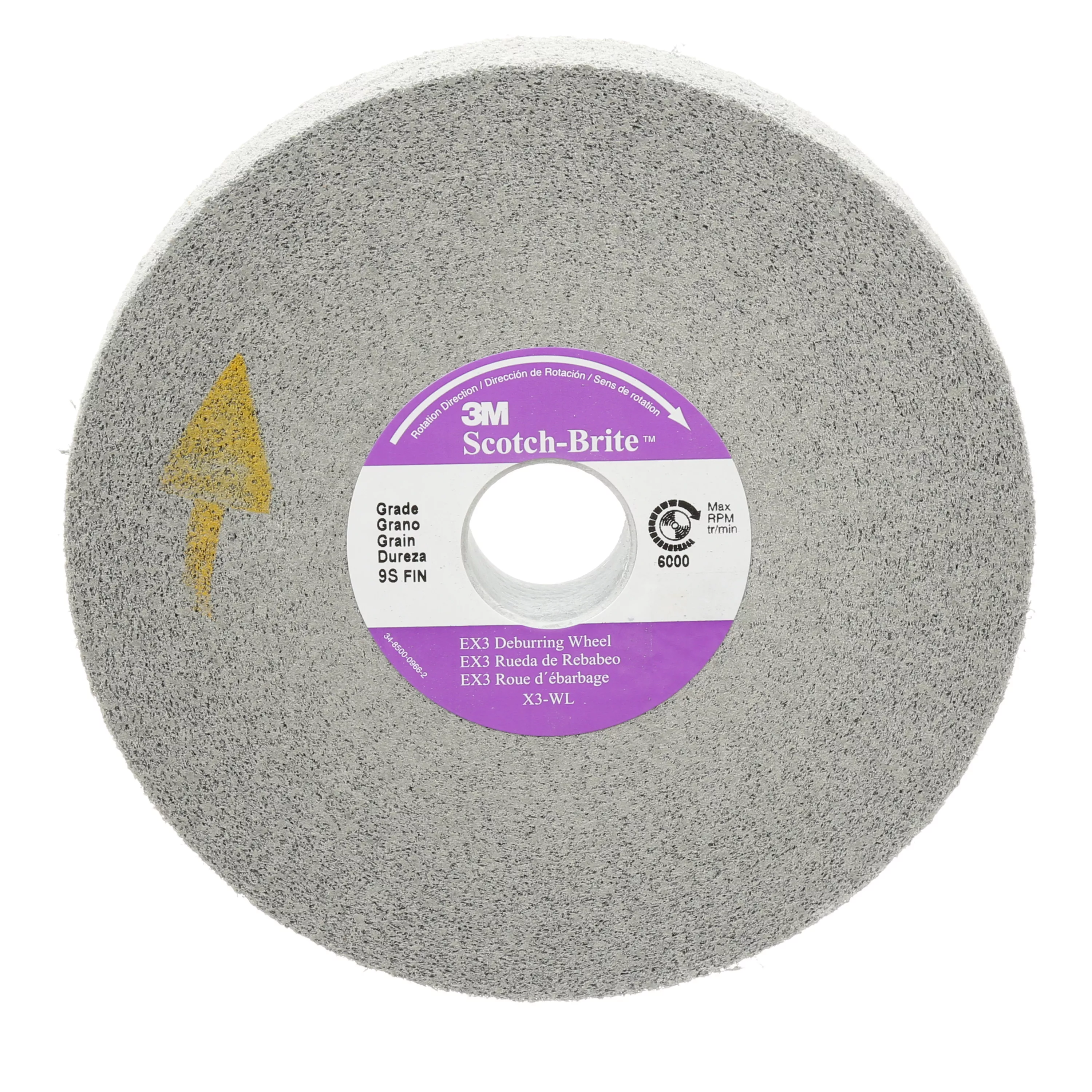

Scotch-Brite EX3 Deburring Wheel is a convolute-constructed, hard, durable deburring wheel suited for applications where edge retention is a must. The wheel performs best when consistently presented with a sharp edge or metal burrs. A unique resin system resists smearing and heat buildup.

- Highest edge retention and durability in the Scotch-Brite™ Deburring Wheel line provides aggressive edge deburring

- Specially engineered to condition sharp edges and metal burrs

- Convolute construction provides a balanced, smooth running wheel throughout product life

- Nonwoven web runs cool and lessens impact on heat-sensitive materials

- Unique resin system produces less smearing, reducing clean and prep time

Product Dimensions |

Imperial | Metric |

| Weight | 0 NULL | |

|---|---|---|

| Width | 0 null | |

| Length | 0 null | |

| Height | 0 null | |

| Diameter | 12 in | 304.8 mm |

| Center Hole Diameter | 5 in | 127.0 mm |

Shipping Dimensions |

|

| Weight | 4.43129 lb |

|---|---|

| Length | 12.51969 in |

| Width | 12.51969 in |

| Height | 1.69291 in |

| Color | Gray |

|---|---|

| Thread Size | Non Pertinent |

| Maximum Speed | 3,000 rpm |

PRODUCT FAQ

-

What is the Scotch-Brite™ EX3 Deburring Wheel used for?

The Scotch-Brite™ EX3 Deburring Wheel is used to achieve a consistent, quality finish on surfaces while also removing burrs and sharp edges.

-

What material can be worked with this deburring wheel?

This deburring wheel works well on aluminum, brass, bronze, carbon steel, cast iron, stainless steel and other metals.

-

How long does this product last?

We cannot provide an exact timeframe since the lifespan of the abrasive product will depend largely upon usage conditions - such as pressure applied during use or the type of materials being polished. However it's best to replace after 1/2 inch remaining in diameter.

-

Is this only hand held or can it be attached to a handheld grinder machine like electric drill bit?

Yes! It fits perfectly into most die grinders and right angle tools with ease using its standard size arbor hole attachment (bore).

-

: Can you give me more information about the X3-WL model specifically?

: Of course! Specifically for surface finishing applications upholding extra fine performance standards widely popular among welders globally; known for providing high performance productivity with consistency when shaping part edges seamlessly by trimming or smoothing existing industrial rust & grinding marks superficially off metal sheet-work projects.

Scotch-Brite™ EX3 Deburring Wheel is an effective tool for deburring, blending, finishing, and polishing edges on various materials such as glass, hard and soft composites, and metals including builder's hardware, medical instruments, metal fabrication, metal implants, plumbing fixtures, and turbine engines. However, it is not recommended for applications where conformability and finishing of flat surfaces are required due to its hard density.

The EX3 Deburring Wheel is available with either silicon carbide or aluminum oxide abrasive mineral. Silicon carbide is a synthetic mineral that is very sharp and commonly used for low-pressure applications such as paint prep and finishing. On the other hand, aluminum oxide is a hard, blocky mineral that provides high cut-rate and long life. Although silicon carbide breaks down faster than aluminum oxide, it produces a finer finish.

Scotch-Brite™ industrial abrasives are unique surface conditioning products that incorporate abrasives into non-woven nylon or synthetic fibers. This combination creates an abrasive system that delivers consistent results for the life of the product. The open-web material runs cool and is load resistant, which keeps the abrasive minerals cutting at high performance by limiting clogging of the fibers.

- Effective for deburring, blending, finishing, and polishing edges on various materials

- Available with silicon carbide or aluminum oxide abrasive mineral

- Silicon carbide produces a finer finish while aluminum oxide provides high cut-rate and long life

- Scotch-Brite™ industrial abrasives deliver consistent results for the life of the product

- The open-web material runs cool and is load resistant, which keeps the abrasive minerals cutting at high performance by limiting clogging of the fibers